Predictive Maintenance in Mining Sector

With early predictive maintenance measures, mining companies can improve their maintenance activities by gathering important data on their machine health and performance; this leads to reduced operational costs and increased productivity of the overall mining operations

What is Predictive Maintenance in Mining Sector?

Waiting until a vital mining asset has broken down to fix it is no longer a prudent, strategic, or economically wise decision if you want to be ready for the next age of industrial innovation

Equipment breakdowns can be costly on several levels –

- Downtime reduces output

- Late-stage failures can be more costly to repair

- In some cases, the asset has to be written off, and there are also wasted labour & energy costs

Unexpected equipment breakdowns can also affect worker safety.

Why should predictive maintenance

be your choice?

Condition Monitoring works in the following three steps:

- Predictive maintenance aims to predict the failures beforehand, and determine the ideal time for performing maintenance activities on an asset so as to minimize the maintenance frequency and maximize its reliability without incurring additional costs.

- The Internet of Things, with the use of sensors and sophisticated analysis techniques for condition monitoring of equipment sets, are essential for a successful predictive maintenance program.

- Predictive maintenance, as opposed to preventative maintenance, identifies a piece of equipment with the potential to cause downtime in the future. This cuts down on the amount of time and money spent on equipment maintenance activities while still preventing unplanned downtime

How mining businesses can benefit from predictive maintenance?

By using an enterprise-level operational data infrastructure mining businesses may be able to:

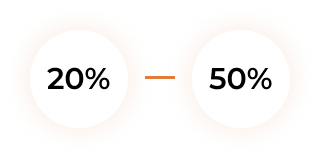

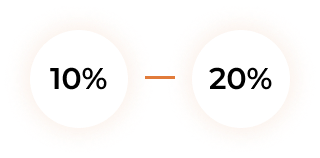

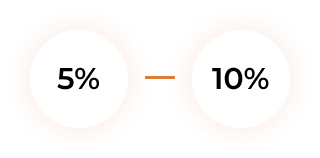

Cut Maintenance Activity time

Boost Equipment Availability

Reduce Maintenance Expenses

Stages of predictive maintenance in the Mining Sector

Our predictive maintenance solution follows several stages to developing a comprehensive predictive maintenance approach for the mining sector.

Our professionals, in collaboration with site maintenance specialists, assess the specific maintenance requirements during the initial stages of scope definition.

We assess your business goals along with the available technologies and the asset mix along with the criticality.

The online condition monitoring application is deployed by the Nanoprecise team in the next stage.

Finally, our Automated Preventive Maintenance Software analyzes all the data remotely and reports on the results on a regular basis.

Nanoprecise has automated alerts and notifications so that client operations, maintenance, and automation departments are all on the same page and can concentrate on their daily tasks.

What makes our solutions unique?

Here are the key features of the Predictive Maintenance Tools from Nanoprecise:

AI and IoT

Our predictive maintenance tools use the combined capabilities of Artificial Intelligence and Industrial Internet of Things to offer an overall accuracy of 99% and forecast the remaining usable life of equipment sets.

Cross-platform scalability

We have got it all covered on your behalf, our solutions come with seamless networking and power options, and can be integrated with leading horizontal and vertical technology stacks, via open APIs. The System can also be deployed in multiple ways, thereby ensuring easy scalability across your operations.

Real-time Information on Machine Health

Dedicated mobile applications and a web portal provide operators with user-friendly data empowers maintenance and reliability professionals with the right data at the right time. It also ensures that you receive notifications and SMS alerts on a regular basis.

Automated End-to-End Solution

Automation that goes beyond data collecting to include automated analysis and connections to other aspects of your digital transformation.

“Plug and Play” Deployment

With a totally wireless deployment and a DIY app for configuration, it is very simple and easy to set up the PdM solution and move or re-deploy sensor hardware

Costs and resources optimization

Spend your time performing maintenance while also enhancing your awareness of potential problems that could result in unplanned downtime.

Why Nanoprecise?

Predictive Maintenance Solution from Nanoprecise combines AI, IoT, and LTE-enabled monitoring, advanced sensors, and prescriptive diagnostics to produce productive outcomes from day one. We employ cutting-edge, scalable technology to monitor equipment health and decrease downtime, which costs the global economy around $100 billion each year.

Nanoprecise employs cutting-edge innovation to provide our clients with accurate prognostic and diagnostic solutions that can predict the remaining usable life of any asset to a 95 % accuracy. Our technologies aid in the construction of 360-degree integrated systems that can predict the remaining useful life of any asset and therefore, minimize your expenses.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.