A Guide to Predictive Maintenance

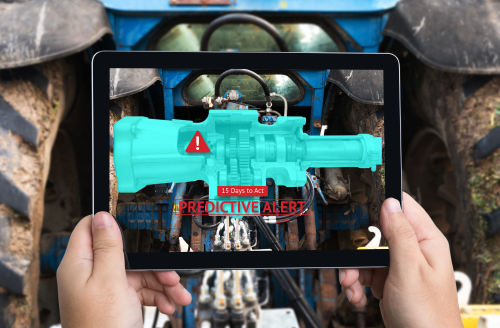

Predictive maintenance is a proactive approach that monitors the asset condition & its performance in real-time, to predict failures before they occur. It uses a combination of wireless Industrial IoT sensors, and data analytics, to identify the warning signs of future failures.

Predictive Maintenance Definition

Predictive maintenance is a technique that involves continuously monitoring the condition of a machine, in order to analyze parameters, such as vibration or temperature, for obtaining meaningful insights about its health and performance. This method of permanent monitoring offers the opportunity to obtain real-time data about the machine’s condition and identify faults that may lead to failures. This helps plan & undertake maintenance activities to prevent unplanned downtime.

To perform predictive maintenance, condition monitoring sensors are installed on the machines to monitor and collect data. This data is then analyzed to identify faults and predict failures. The sensors collect and analyze complex data about the machine health & performance, to predict when it will fail. The Predictive Maintenance Solution then identifies the issues developing in machine components at an early stage, and prevents unplanned downtime. It notifies maintenance & reliability professionals when assets start to show initial signs of failure, thereby giving enough time for engineers & technicians to schedule repairs. It offers the potential to maximize the machine uptime, by predicting faults and allowing enough time to schedule repairs, without affecting production.

How does Condition Monitoring work?

Predictive maintenance provides many advantages to manufacturers and operators:

- It offers a way for technicians and engineers to predict when an asset will fail. This prediction and notification give enough time for them to schedule repairs, thus reducing unplanned downtime in the future.

- Data analytics also provide organizations with the opportunity to produce better products at a faster rate without sacrificing quality or consistency. By collecting and analyzing machine health and performance data before an asset fails, predictions can be made about which assets need attention. Furthermore, predictive maintenance helps detect developing issues before they become major problems.

- Predicting failures in advance offers maintenance & reliability professionals to allocate resources prudently, thus saving significant time and cost involved in the maintenance activities. This is mainly because energy & funds spent only on necessary maintenance activities and not on routine inspections & replacements.

- Predictive maintenance facilitates timely repairs of components, thereby allowing manufacturers to maintain machines & equipment sets in the optimal condition.

- Predictive maintenance also allows manufacturers to maintain customer demand by meeting deadlines and providing consistent service delivery. Organizations that adopt predictive maintenance programs usually experience improved customer satisfaction and increased profitability.

Disadvantages of Predictive Maintenance

Predictive maintenance, like any other practice, is not without its limitations. Some of them are detailed below:

- Implementing a predictive maintenance solution is a costly affair, and a significant component of it can be attributed to the cost of installing necessary technology.

- Change management and training the staff is another challenge as the employees will have to adopt newer technologies and practices over traditional methods.

- Although predictive maintenance offers companies the potential to produce better products at a faster rate without sacrificing quality or consistency, it will only prove fruitful when implemented appropriately.

- Not all industrial assets may incur costly failures. For those assets which cause minimal downtime or incur lesser maintenance cost, it may be beneficial to adopt a preventative maintenance approach rather than a predictive one.

The advantages of predictive maintenance are clear and include cost savings by preventing unplanned downtime in the future. While Predictive Maintenance has some limitations, they can be overcome by examining the company’s needs and capabilities before implementing maintenance measures.

How Much Does Predictive Maintenance Cost?

Predictive maintenance is not a new concept and has been around since the 1970s. The idea of predicting when an asset will fail and then taking preventive measures, is a very old one.

On average, predictive maintenance systems cost about $2 per machine hour. But this is just for the equipment and software necessary to get started. It is essential to note that companies may need to pay someone who knows how to program the system and set up the sensors. Alternatively, most of the manufacturing organizations partner with Predictive Maintenance solution providers for implementing a PdM regime as well as to train their employees.

Many companies also use predictive maintenance for more than just machinery. It can also be used for other assets like computer networks, HVAC systems, and even water pipes! You may not use the data from all of these assets already, but it’s worth considering if you’re looking into making your business more efficient.

Return on Investment

The process of predictive maintenance is implemented to increase the reliability and quality of production, reduce downtime and improve uptime. Predictive maintenance has a direct and positive impact on all three areas:

- Quality: It reduces defects and machine downtime, which can result in increased productivity.

- Productivity: Predictive maintenance helps production operators achieve higher outputs because it minimizes downtime.

- Uptime: Predictive maintenance helps to keep the machine in optimal condition, thereby increasing uptime (time that machine is operational). Increased uptime results in improved equipment utilization rate, less inventory carrying costs and increased customer satisfaction with products/services provided by the organization.

According to Deloitte, predictive maintenance results in:

5-10% Material Savings

5-10% reduction in

overall maintenance costs

10-20% increase in equipment

uptime & availability

How can Nanoprecise Sci Corp Help you?

Nanoprecise Sci Corp is an automated AI-based predictive maintenance solution provider that facilitates early detection of even small changes in machine operations well before they impact production or cause downtime. Nanoprecise specializes in the implementation of Artificial Intelligence and Industrial IoT technology for predictive asset maintenance and condition monitoring. The AI-based solution offers real-time predictive information about the genuine health and performance of industrial assets.

Nanoprecise helps customers across the world to increase production and reduce unplanned downtime while allowing maintenance teams to focus on value added activities rather than routine data gathering and analysis.

We use an agile service approach, where we analyze six available data points from the equipment sets, to offer actionable insights that significantly enhance the maintenance of critical assets and facilitates effective failure management. We have helped countless asset-intensive firms reduce machine downtime, improve performance and dependability while cutting maintenance costs by focusing the manufacturers’ expert-level personnel on true value-add activities.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.