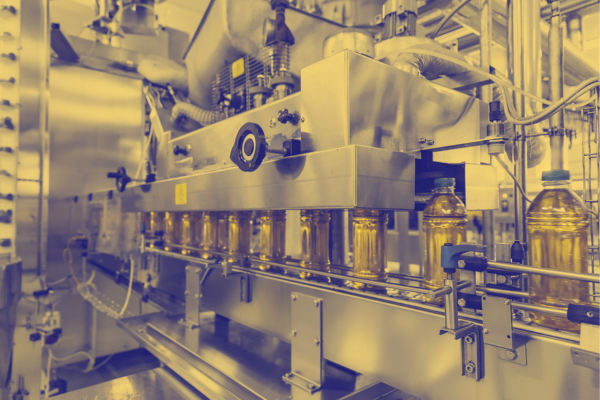

Food & Beverage

In the dynamic and fast-paced world of the food and beverage industry, the challenges of unplanned downtime and environmental impact are ever-present. Operating in an environment where production efficiency and product integrity are paramount, the industry faces disruptions that can affect not only seamless production but also contribute to sustainability concerns. Forward-thinking businesses in the food and beverage sector are therefore increasingly adopting predictive maintenance to navigate these challenges. This proactive approach empowers manufacturers to foresee potential equipment issues, strategically minimizing unplanned downtime, and addressing environmental considerations associated with sudden failures.

Industry Challenges

Preventing Contamination through Human Intervention

Adhering to stringent quality and health norms, coupled with maintaining rigorous safety standards, is a paramount challenge in the food and beverage industry. Ensuring that human intervention, including data collection methods to monitor equipment condition aligns seamlessly with these standards becomes a critical aspect of preventing contamination risks.

Unplanned Downtime and Batch Loss

Unplanned downtime poses a significant challenge in the food and beverage industry, potentially resulting in lost batches and disrupting carefully orchestrated production schedules. This critical issue demands a proactive approach that can mitigate the impact of unforeseen issues and enhance the overall operational resilience of manufacturing processes.

Manual Data Analysis

The reliance on manual data analysis, particularly in tasks like vibration analysis, presents a notable challenge for the food and beverage industry. This process demands a high level of expertise and experienced maintenance teams to accurately interpret the collected data. Moreover, the associated costs of vibration monitoring equipment, coupled with the necessity for regular maintenance and calibration, contribute to an increased overall cost of upkeep. Addressing this challenge is crucial for optimizing maintenance processes and achieving cost efficiency in the industry.

Applications

Recirculation Fans

Compressors

Extruders

Let us show you how!

Our cutting-edge solutions are tailored to address the unique challenges faced by your industry, ensuring the highest standards of quality, safety, and operational efficiency. By seamlessly integrating with your processes, we empower manufacturers to eliminate unplanned downtime, reduce their carbon emissions and improve their overall operational efficiency. Choose Nanoprecise for a transformative journey that ensures the integrity of your production processes, minimizes disruptions, and maximizes the overall productivity of your manufacturing operations.