MachineDoctor: The First 6-in-1 Wireless IOT Sensor for Predictive Maintenance

Easy to configure and deploy, the MachineDoctor sensor is a wireless battery-operated sensor that measures 6 machine health parameters. With a cellular or a wifi connection the sensor automatically transmits data to the cloud for analysis.

MachineDoctor a Perfect Fit for Your Assets

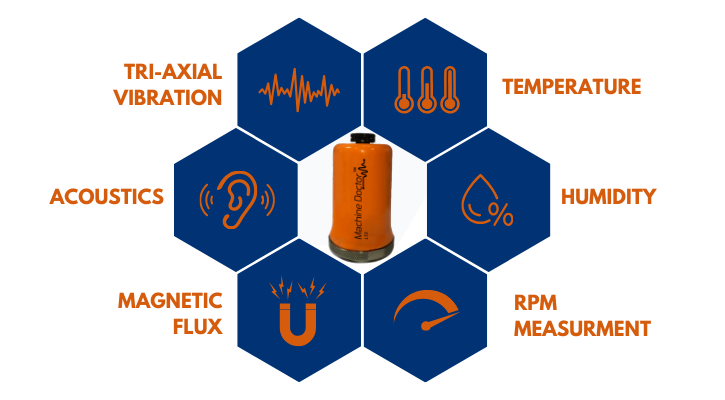

Plug and Play, 6-in-1 Parameter Measurement

The sensor can detect and measure Triaxial Vibration, Acoustic Emissions, Temperature, True RPM, Humidity, and Magnetic Flux.

Fits your Operations, Wherever They May be!

Leveraging its Cellular or Wifi connection and edge computing functionality, the sensor ensures a seamless data transfer regardless of your infrastructure.

Self-Sustaining

The completely wireless & low battery consumption sensor can run off its internal battery for years!

The MachineDoctor Line of Predictive Maintenance Sensors

MachineDoctor – WiFi

Machine Doctor WiFi is a completely wireless battery-operated edge sensor that uses WiFi routers to take data to the cloud for analysis.

It measures 6 parameters in a single sensor, including: Vibration, Acoustic Emission, Temperature, Humidity, True RPM & Magnetic Flux. Comes with Magnetic Mount, Stud Mount, or Adhesive installation options so you don’t have to worry about any extra IT infrastructure. NbIot/CAT-M1/LTE/Wifi/Bluetooth available

MachineDoctor – LTE

Machine Doctor – LTE offers flexibility to connect to the internet via its inbuilt ESim which has coverage of over 100+ countries across 350+ network service providers.

It measures 6 parameters in a single sensor, including: Vibration, Acoustic Emission, Temperature, Humidity, True RPM & Magnetic Flux. Comes with Magnetic Mount, Stud Mount, or Adhesive installation options so you don’t have to worry about any extra IT infrastructure. NbIot/CAT-M1/LTE/Wifi/Bluetooth available

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.