“The ROI of Energy Centered Maintenance (ECM) goes beyond financial gains – it’s a foundational shift. ECM not only delivers energy savings, uptime, and extended asset life, but it also aligns maintenance with ESG goals, transforming it from a cost-center into a strategic growth driver that protects margins and drives long-term success“

Chief Evangelist Officer, Nanoprecise

For decades, Reliability-Centered Maintenance (RCM) has been the gold standard in asset management, particularly when it comes to machinery where failure can lead to significant downtime and costly repairs. It prioritizes assets based on their criticality to operations, helping organizations prevent catastrophic failures. However, this focus on “critical” machinery can sometimes overlook a vast majority of assets that, while not immediately critical, still lead to inefficiencies, increased energy consumption, and higher operational costs.

That’s where Energy Centered Maintenance (ECM) comes in. ECM enhances RCM by adding a new layer of insight focused on monitoring energy consumption, bringing energy efficiency into the spotlight alongside reliability.

Think of it like this: RCM has always been akin to black-and-white television – it’s reliable, functional, and effective. But now, with ECM, you’ve added color to the picture. The same machinery, the same maintenance goals, but ECM provides a new lens through which to view asset performance. It’s not about replacing what works, but about putting energy consumption at the core of maintenance planning – broadening its scope and allowing companies to see both reliability and energy performance in full color.

The scale of energy waste

Electric motors (and the equipment they drive) are the largest consumers of electricity in the industrial sector, responsible for approximately two-thirds of global electricity consumption in this space. Among these, mid-sized motors (ranging from 0.75 kW to 375 kW) account for the largest share of electricity usage overall. However, large electric motors (375 kW above), despite making up just 0.03% of the total motor stock, account for nearly 23% of all motor power consumption, meaning they have a disproportionately large impact on organizational energy costs. The International Energy Agency (IEA) estimates that up to 25% of electric motor system energy consumption could be saved through cost-effective efficiency measures. This represents a massive opportunity for organizations to reclaim substantial amounts of lost profit while significantly reducing energy waste on a global scale.

How does the ECM approach work in practice?

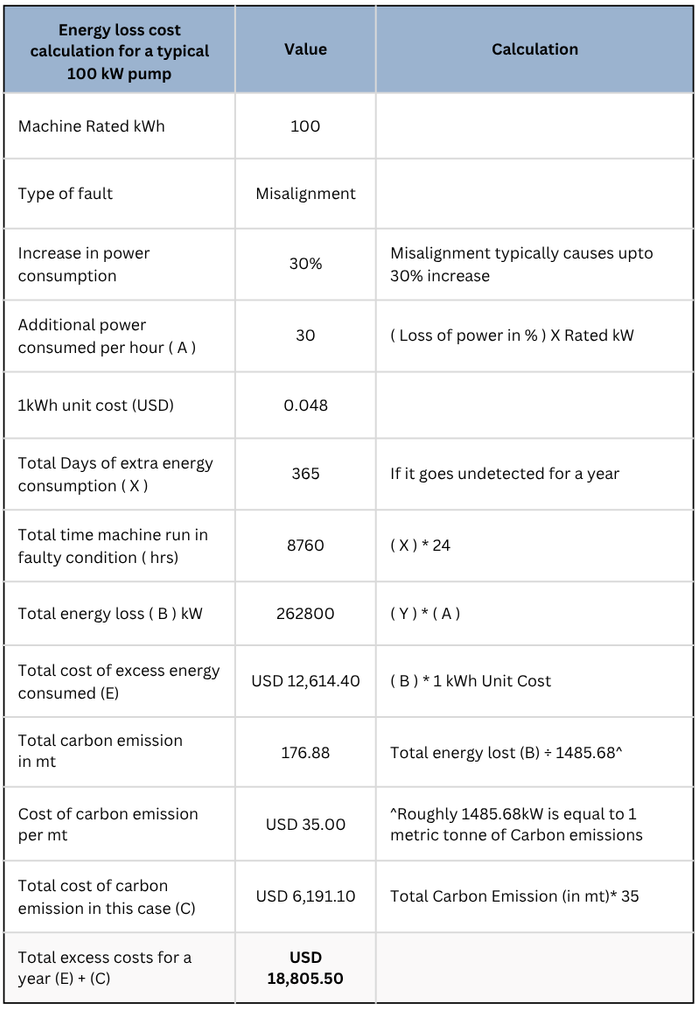

While the above big-picture numbers are eye-opening, ECM also delivers substantial value at the micro level. Take the example of a mid-horsepower pump (~100 kW motor) – a common component in many industrial environments. If the pump develops a slight imbalance or misalignment, it may produce minor vibrations. These may not be severe enough to trigger alarms in traditional, failure-oriented monitoring systems. Moreover, the pump may be classified as a support asset and not considered critical, further reducing the likelihood of detection.

Yet even without failure, that imbalance can lead to significant energy loss – something that often goes unnoticed and adds up to substantial financial impact. Have a look at the rough, back-of-the-envelope calculations below to get a sense of how much financial impact a single inefficient motor can have:

In an energy-focused monitoring system, such inefficiencies would be flagged, regardless of the asset’s criticality, enabling maintenance teams to address the issue before it results in wasted energy and higher costs.

By evaluating all assets through the lens of energy use, ECM ensures that no equipment is ignored, creating opportunities to reduce waste, improve operational efficiency across the entire plant and positively impact the bottom line.

The key difference in approach to note is that rather than seeing energy efficiency as an afterthought, ECM brings it into the conversation at the outset, allowing organizations to enhance their existing reliability-focused framework by making energy optimization a key consideration for all assets (not just a few).

With ECM, the emphasis is on energy-conscious maintenance, helping teams focus not only on keeping critical assets running but also on improving energy efficiency across the board.

Shifting the mindset: From asset-level to component-level thinking

One of the biggest shifts that ECM enables is the move from an asset-level mindset to a component-level mindset. Traditionally, maintenance strategy has focused on entire machines – whether it’s HVAC systems, air compressors, boilers, or dryers – and categorized them based on their criticality. But with ECM, the focus shifts to the individual components that drive performance, such as motors, pumps, and fans.

Instead of asking, “Which HVACs should I monitor?” ECM encourages thinking, “How many of a specific type of motor or pump do I have in my plant?” By standardizing monitoring across similar components, organizations can gather more consistent data, identify trends, and gain a clearer understanding of energy consumption.

This approach creates plant-wide visibility, allowing organizations to monitor all assets (critical or non-critical) based on their energy usage. By scaling this mindset across sites, organizations can achieve true enterprise-level transformation, ensuring that all assets are operating at their most efficient, regardless of their criticality.

Energy Centered Maintenance For All

Many maintenance practitioners may be surprised to learn that some organizations have been using energy-based equipment monitoring for quite some time. These are the absolute top 10 percent – industry leaders known for setting the gold standard in maintenance. They’ve long recognized that monitoring energy usage is not only crucial for the bottom line and sustainability, but also for enhancing risk detection within their asset management frameworks.

For years, these leading organizations have developed their own in-house systems to track and optimize energy use, leveraging custom-built solutions made possible by their resources. While effective, these systems are often complex, require ongoing upkeep, and aren’t easy to scale.

With Nanoprecise’s approach to ECM (what we call Energy-Centric Predictive Maintenance) we’re making energy-monitoring accessible, scalable, and practical for the remaining 90% of companies who are either playing catchup or just beginning to realize its value. By bringing energy-centered maintenance into the mainstream we’re ensuring it’s no longer the privilege of a few but a core capability every manufacturer can integrate into their maintenance strategy.

Energy Centered Maintenance Case Study

Learn how a global leader in chemical manufacturing improved equipment health visibility and energy efficiency at its critical polymer plant in Spain. By adopting Nanoprecise’s ECM solution, the plant identified two pieces of equipment with abnormal vibrations, one of which was consuming 20% more energy than expected. Find out how this proactive approach helped avoid €50,000 in equipment losses and saved €9,500 in excess energy: Read the full case study here.

Reevaluating criticality and downtime costs

In traditional maintenance strategies, criticality assessment determines which assets are prioritized for maintenance based on their potential to cause downtime. However, the cost of downtime is not always directly correlated with asset criticality. For example, a failure in a non-critical asset early in the production process may have minimal impact on overall operations, whereas a failure later in the process may lead to substantial losses. Traditional criticality assessments often miss the broader picture of how less-critical assets can still disrupt operations. By incorporating ECM, organizations can assess asset performance through the lens of energy consumption, allowing them to identify non-critical assets that could cause inefficiencies or slowdowns. This shift in thinking broadens the scope of maintenance decisions, considering both criticality and energy usage, and helps mitigate the risk of overlooking less obvious but impactful inefficiencies.

Bridging the divide

There has historically been a divide between RCM experts, who rely on time-tested methodologies, and technology advocates, who champion the use of advanced solutions like AI and predictive analytics. ECM bridges this gap by highlighting an approach where technology can be seamlessly integrated into traditional practices, enhancing rather than disrupting existing workflows. With ECM, maintenance professionals can continue using their trusted reliability strategies while benefiting from the added advantage of modern technologies, which help streamline operations, improve accuracy, and enhance energy efficiency. This partnership between traditional expertise and modern technology creates a more effective, data-driven maintenance strategy – one where best practices are continuously re-evaluated through a technological lens. For example, if a technology can fully automate a process, it may prompt a reassessment of whether the existing manual approach is still relevant.

Beyond reliability: How Energy Centered Maintenance can shape the future

The true power of ECM lies in its ability to drive both cultural change and measurable business impact. In a world where ESG goals are no longer optional, ECM offers a way to align financial performance with sustainability. By providing a continuous view of plantwide energy consumption, it enables smarter, data-driven decisions on when to intervene and how best to optimize asset performance; directly translating into cost savings.

Whether by reducing energy waste or improving equipment performance, ECM provides tangible benefits that enhance profitability. Key performance metrics such as mean time to repair (MTTR), mean time between failures (MTBF), equipment lifespan, and overall equipment effectiveness (OEE) can all see meaningful improvement. By placing energy efficiency at the core of asset management, ECM equips organizations with the tools to optimize both reliability and resource use. As maintenance practices continue to evolve, this approach will be essential in helping companies boost operational efficiency, reduce costs, and ensure that every asset – regardless of its criticality – delivers value to the bottom line.

Ready to take the next step? Watch our webinar on Energy Centered Maintenance (ECM) to learn how this powerful approach can help you tackle energy waste and unplanned downtime through a single, data-driven strategy: ▶️Watch now▶️

About the Author

Kevin Clark brings over 35 years of experience in global operations leadership, specializing in advanced technologies for operations, engineering, and asset management. He previously served as Vice President at Fortive Corporation (Fluke/Accruent) and Falkonry AI, where his strategic leadership drove growth in Enterprise Asset Management and AI/Predictive Technologies. Kevin’s career also includes senior roles at Caterpillar and Johnson & Johnson, in engineering leadership. A long-standing member of the Society of Maintenance & Reliability Professionals (SMRP), Kevin has been a Certified Maintenance & Reliability Professional (CMRP) since 2004 and serves on various industrial advisory boards.