Transforming Manufacturing Through AI for Energy Efficiency

Unlocking Energy Efficiency in Manufacturing with AI

Introduction

In today’s rapidly evolving industrial landscape, harnessing the power of AI for energy efficiency is not just a possibility – it’s a strategic imperative. At Nanoprecise Sci Corp, we believe that the synergy of artificial intelligence and energy efficiency is the driving force behind the transformation of manufacturing as we know it. We are dedicated to unleashing the potential of artificial intelligence to optimize energy consumption and drive sustainability within manufacturing.

The Energy Efficiency Challenge

Manufacturers today are confronted with a dual challenge: to enhance productivity while reducing their carbon footprint. Striking this delicate balance requires a proactive approach that transcends conventional methods. Inefficient energy usage not only impacts the bottom line but also contributes to environmental degradation. As the pressure to align with sustainability goals grows, the need for AI to redefine the landscape of energy consumption becomes evident.

AI for Energy Efficiency: A Game-Changer

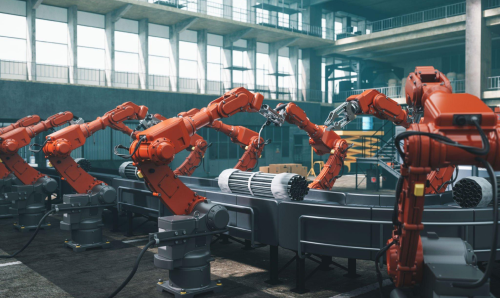

As energy optimization in manufacturing becomes paramount, embracing AI-powered solutions is the game-changer operators have been seeking. Our innovative approach combines the prowess of AI with the pressing need for energy efficiency, resulting in a holistic solution that revolutionizes manufacturing processes. With our AI for energy efficiency solutions, your manufacturing facility becomes an intelligent entity that adapts, learns, and evolves – all while significantly reducing energy waste.

Enhancing Energy Efficiency with Real-Time Insights

Imagine sensors and AI algorithms working in harmony, delivering real-time insights into your energy consumption patterns. This convergence of Artificial Intelligence and energy efficiency ensures that you’re always in control. Our State-of-the-art IoT sensors seamlessly capture data from equipment and processes, feeding it into advanced AI algorithms that analyze, predict, and prescribe actionable strategies. It’s a dynamic partnership that empowers you to make informed decisions, optimize energy consumption, and minimize waste.

Predictive Maintenance for Energy Excellence

Our AI solutions go beyond real-time insights. They are the guardians of your machinery’s well-being, predicting maintenance needs and preventing energy-sapping breakdowns. Through predictive maintenance powered by artificial intelligence, we ensure that your equipment remains at peak efficiency, consuming only the energy it requires. It is a game-changing shift that not only saves energy but enhances operational reliability, ultimately boosting your bottom line.

Nanoprecise Sci Corp

At Nanoprecise Sci Corp, we’re not just providers of AI solutions – we’re partners in your journey towards energy efficiency excellence. With a proven track record of deploying AI-based predictive maintenance solutions, we understand the nuances of your industry. We’re dedicated to tailoring our AI for energy efficiency solutions to your specific manufacturing needs, ensuring that you unlock every possible avenue for energy savings.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.