Solving the Real Problems with Predictive Maintenance

“The challenge was never about getting more data. It is about making the data work together, at the speed of the problem.”

Rituraj Ubnare, Principal Architect, Nanoprecise.

Today’s industrial operations are more connected than ever. Vibration sensors, energy meters, and CMMS platforms are all capturing valuable insights, each contributing a vital piece to the equipment health puzzle.

At Nanoprecise, we saw an opportunity: what if these systems could speak the same language?

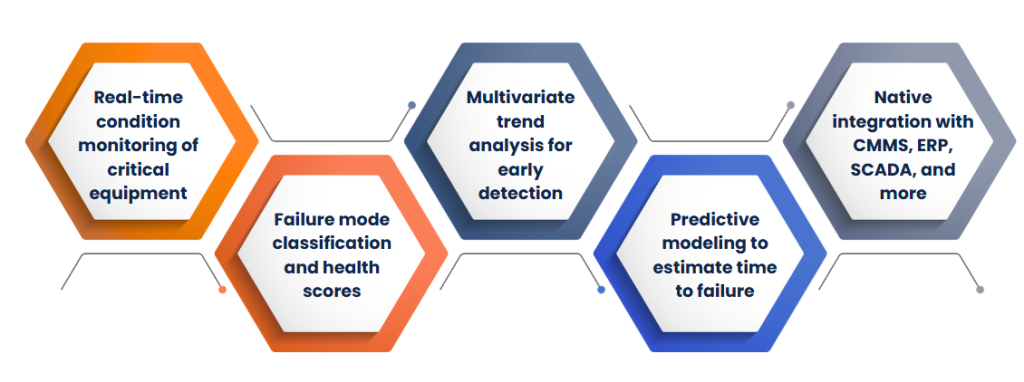

That’s exactly what we are built for. Our platform brings together multivariate sensor data and operational records into a unified, real-time view, allowing maintenance teams to move from scattered snapshots to complete clarity. Instead of interpreting isolated signals, teams gain the ability to see patterns, anticipate failures, and act proactively.

Because when your data flows together, your decisions do too. And in Industry 4.0, that’s not just efficiency, it’s a competitive advantage.

Engineered for Scale, Built for the Real World

Once the flow is unlocked, the next step is scale. That’s where our architecture shines.

From the beginning, we built Nanoprecise to handle the complexity and volume of modern operations, whether you’re starting with a few machines or deploying across hundreds of sites globally. Our edge devices continuously stream structured, high-fidelity data across six parameters, while our backend processes millions of data points effortlessly to deliver timely, actionable insights.

But scalability isn’t just about speed or volume, it’s about fit.

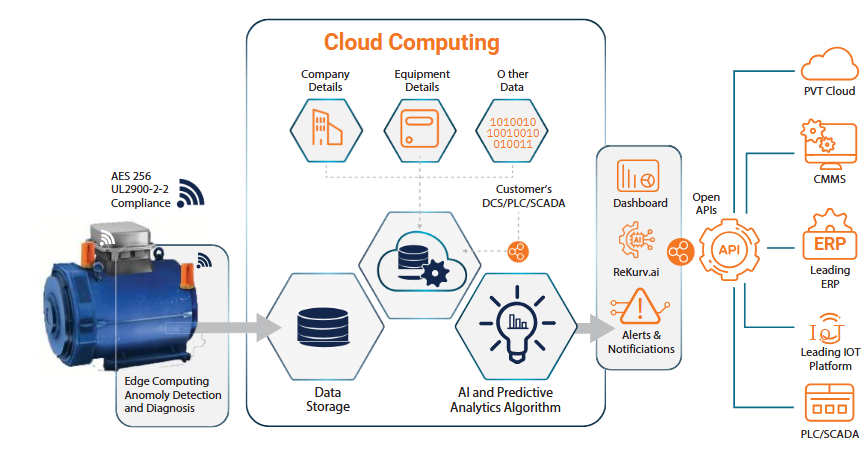

With open APIs and a modular design, Nanoprecise integrates naturally into your existing digital ecosystem, whether it’s CMMS, ERP, SCADA, or cloud data lakes. That means you don’t have to choose between innovation and interoperability.

“We didn’t build another tool; we built a way to bring your tools together.”, Arun Patlolla, VP Engineering, Nanoprecise.

By combining unified data, real-time analytics, and seamless integration, Nanoprecise helps maintenance teams stay ahead, no matter how large the operation or how complex the asset base.

Inside the Nanoprecise Architecture: How It All Comes Together

Edge Intelligence: Smart Sensors with Built-in Processing

It all begins at the edge.

Our proprietary multi-sensor devices are mounted directly onto industrial equipment to continuously capture a rich set of high-frequency signals. patterns, and contextual intelligence, so you can go from “I think it’s fine” to “I know what to do next.”

But these aren’t just data collectors. Each sensor is a smart endpoint, built with a powerful combination of proprietary hardware and firmware that allows it to filter out noise, extract critical features, and even perform initial anomaly detection right on the device.

This local processing capability significantly reduces the amount of data that needs to be transmitted, minimizing latency, conserving bandwidth, and enabling faster, more responsive decision-making.

What’s more, every sensor is fully configurable. From sampling rates and signal thresholds to alert parameters and connectivity options (Wi-Fi, LTE), teams can tailor each device to match the specific needs of their environment, whether it’s a remote mining site or a high-throughput production line.

A Scalable, Resilient Data Backbone

Once data leaves the edge, it travels through a high-performance, low-latency pipeline built for industrial realities.

Our event-driven architecture ensures sub-second latency while remaining resilient to the unexpected. Whether facing intermittent connectivity or bandwidth fluctuations, our built-in retries, buffering, and failover mechanisms ensure that your data arrives intact, with no blind spots. Data is transmitted securely via HTTPS over TLS and can be routed to our cloud or deployed in a customer-hosted environment.

And because we know one cloud doesn’t fit all, our platform is fully cloud-agnostic, offering seamless integration with AWS, Azure, GCP, or any customer-preferred provider.

But a fast pipeline is only as good as the platform behind it.

That’s why we built a cloud-native, containerized microservices platform that leverages technologies like Apache Kafka and robust real-time data pipelines built for distributed processing, complex event handling, and scalable analytics of millions of data points in real time. From automated health indexing to time-to-failure predictions, this scalable engine powers deep insights across entire fleets.

Benefits You Gain

Built to Handle Volume, and Built to Adapt

As operations scale, so does data complexity. That’s why we’ve taken a modular, multi-database approach, ensuring performance and agility no matter the workload.

Instead of relying on a single database to handle everything, we use multiple purpose-built systems: time-series databases for sensor streams, relational databases for configuration, and specialized stores for logs and interactions. This separation enables faster queries, optimized storage, and better scalability across use cases.

“Architecturally and from a design perspective, it’s better to use multiple types of databases based on the use case.” Arun Patlolla, VP Engineering, Nanoprecise.

This flexible structure lets us scale horizontally, processing high-frequency data streams like vibration or energy usage without breaking stride. It’s this foundation that powers Condition Intelligence, our multivariate AI engine, that learns from patterns, correlates cross-parameter anomalies, and helps prevent downtime before it happens.

Because handling data on a scale isn’t a nice-to-have, it’s essential to deliver actionable intelligence, right when you need it.

Designed to Fit, Built to Deliver

In the real world, no two tech stacks are the same. Legacy systems, proprietary protocols, and mixed IT/OT environments are the norm, not the exception. That’s why we built Nanoprecise to be integration-ready from the ground up.

Our architecture embraces interoperability with:

- Open API access to essential data streams

- Secure authentication and role-based access control for enterprise-grade deployments

- A flexible integration framework that connects seamlessly with platforms like SAP, Maximo, Azure, and more

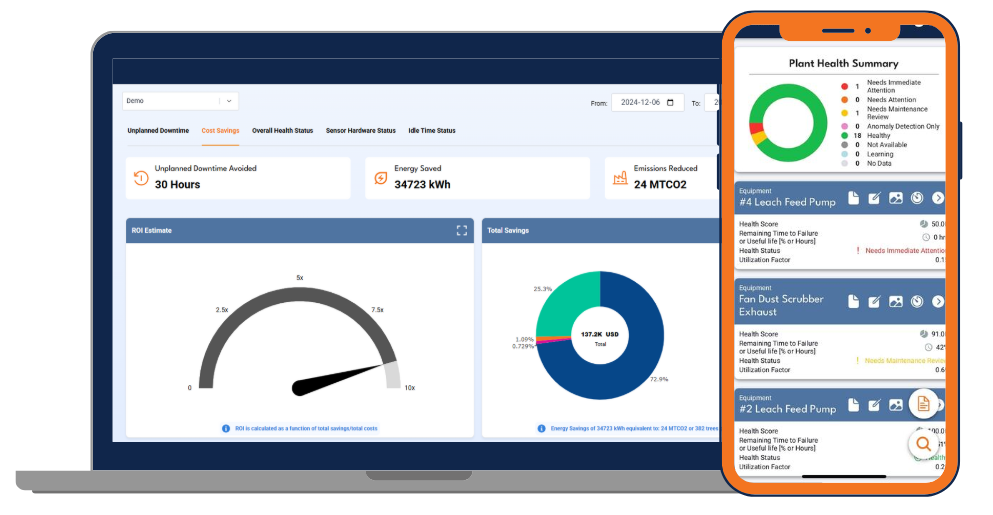

But this isn’t just about connecting software. It’s about creating a unified ecosystem. Whether it’s our Multiview Dashboard, the NRG Monitor, ReKurv.ai, or our 6-in-1 edge sensors, every component of Nanoprecise is designed to work together and work with what you already have.

You don’t need to rip and replace. You just need a system that meets you where you are, and scales with where you’re going. By closing the gap between sensors and insights, Nanoprecise empowers maintenance teams to stop reacting and start anticipating. We’re not just delivering data, we’re turning it into timely, reliable, and actionable intelligence that drives results from day one.

The Payoff: Energy Centered Maintenance That Moves Your Business Forward

Energy Centered Maintenance, a step above Predictive Maintenance, isn’t just about gathering more data, it’s about unlocking the right signals at the right time, so your machines can speak before failure strikes. When equipment can tell you how it’s performing, what’s degrading, and what needs attention, you’re not just reacting to problems; you’re proactively driving efficiency, sustainability, and operational excellence.

At Nanoprecise, we’ve built more than one monitoring system. We’ve engineered a fully integrated architecture that scales with your operations, adapts to diverse environments, and evolves alongside your goals.

And that architecture isn’t just a technical achievement; it’s a business enabler.

It means:

- Faster deployment across complex facilities

- Seamless interoperability with your existing tech stack

- A reliable path to intelligent, energy-centered maintenance at scale

We’re not just building predictive tools. We’re building a foundation that makes predictive maintenance practical, actionable, and valuable across industries.

Looking to see how it fits into your operations?

If you’re ready to explore now, our team is here to show you how Nanoprecise can plug directly into your ecosystem.

Let’s make your data work harder, and your maintenance smarter.

About the Author

Rituraj Ubnare is the Principal Architect at Nanoprecise Sci Corp, where he leads the design and implementation of AI + IoT predictive maintenance solutions for industrial customers worldwide. With over 15 years of experience in system architecture, cloud applications, and AI-driven platforms, Rituraj brings deep technical and strategic insight into building scalable, GenAI-powered SaaS products.

His past roles at Quick Heal, SEQRITE, and Amdocs reflect a strong foundation in cybersecurity, real-time analytics, and big data ecosystems across on-prem and cloud environments. Throughout his career, he has championed the adoption of ML-driven innovations in telecom, manufacturing, and financial services, enabling organizations to accelerate decision-making and operational efficiency.

Rituraj is passionate about engineering products that sit at the intersection of Industrial IoT, artificial intelligence, and edge-cloud architectures, pushing the boundaries of what’s possible in predictive maintenance and industrial automation.