Summary: This blog shares how Nanoprecise Enterprise Metrics helps organizations prove the ROI of predictive maintenance by turning asset data into business insights. Learn how it connects downtime, cost savings, energy, and sustainability to profitability and growth.

“Catching the conveyor fault alone justified the entire investment in our predictive maintenance system. Once we caught it, the team scrambled to calculate what that downtime would’ve cost us. The numbers were huge, and we knew we needed to keep tracking our savings.”

— Assistant Manager of Reliability, Leading Potash Producer

A Changing Conversation in Maintenance

Industrial maintenance has come a long way. What was once viewed as a cost center is now recognized as a driver of profitability, sustainability, and competitive advantage. Organizations have invested in sophisticated monitoring systems, advanced analytics, and predictive models that can anticipate failures before they happen. They can optimize energy use, extend equipment life, and minimize costly disruptions that once brought operations to a standstill.

But progress has also created a new challenge: how to make this value visible across the enterprise.

On the plant floor, reliability engineers speak the language of utilization rates, Mean Time Between Repairs (MBTR), and health scores. In the boardroom, executives focus on ROI, cost avoidance, risk mitigation, and sustainability targets. Both are measuring success, but through different lenses.

What’s missing is a common thread that connects technical outcomes to financial and strategic priorities, a way to show how every maintenance intervention contributes not just to asset reliability, but to business performance, sustainable action, and long-term growth.

Source: Polese, F., Gallucci, C., Carrubbo, L., & Santulli, R. (2021). Predictive Maintenance as a Driver for Corporate Sustainability: Evidence from a Public-Private Co-Financed R&D Project. Sustainability, 13(11), 5884. https://doi.org/10.3390/su13115884

The Ideal World

In most organizations today, there’s a gap between how success is measured on the plant floor and how it’s communicated in the boardroom. Engineers focus on equipment health, Mean Time Between Repairs, and utilization rates, while executives care about ROI, avoided costs, and sustainability progress. Both perspectives are valid, but they rarely line up in the same conversation.

In the ideal organization, this translation gap doesn’t exist. A quarterly review doesn’t just highlight improved asset health or fewer failures. It begins with statements like:

- “Predictive maintenance avoided 48 hours of unplanned downtime, saving $127,000 in lost production.”

- “Energy optimization reduced usage by 18,838 kWh, cutting 13 metric tons of CO₂, equivalent to planting 207 trees.”

- “The program delivered a 9x ROI while extending MTBR to 584 days.”

From there, the discussion flows into how those results were achieved, what can be replicated, and where to focus next for greater impact.

Operational metrics such as utilization rates, repair intervals, and idle times do not disappear; they are reframed within the larger business narrative.

The Gap We’ve Learned to Accept

In most organizations, maintenance, energy, and finance teams operate in silos.

Maintenance dashboards show asset health and alerts. Energy reports track consumption. Finance manages budgets and spending. Each function optimizes for its own priorities, and each produces reports that make sense internally, but don’t always connect across departments.

Over time, this separation feels normal. But it hides the bigger story: how a single intervention can ripple across the business, preventing revenue loss, lowering emissions, and extending asset life, all at once.

Closing this gap isn’t about more data. It’s about creating a single source of truth where the value of maintenance is visible, measurable, and understood by everyone.

The Purpose of Enterprise Metrics

Nanoprecise introduced Enterprise Metrics with a clear objective: to empower its customers by making maintenance outcomes visible, credible, and business-relevant.

Its purpose is simple but transformative, to connect every maintenance action directly to measurable business outcomes, in real time, with full transparency.

By integrating data from Condition Intelligence, NRG Monitor, and real maintenance feedback, Enterprise Metrics provides a unified, enterprise-wide view of:

Enterprise Metrics is more than a consolidated dashboard. It’s a translation layer between plant-floor activity and boardroom strategy.

From Intervention to Enterprise Impact

The Enterprise Metrics dashboard makes the story of maintenance visible in a way that resonates beyond the plant floor. Rather than forcing teams to stitch together scattered reports, it provides a single, integrated view of cause and effect, showing not just what was fixed, but what was gained.

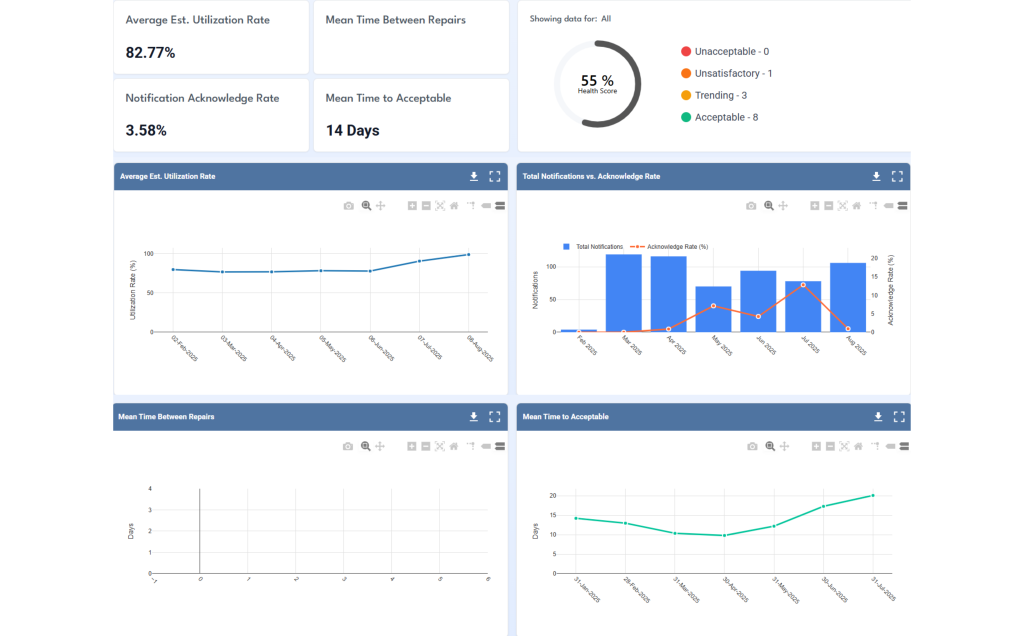

On one screen, leaders can see operational performance come to life. Metrics such as Utilization Rate, Mean Time Between Repairs (MTBR), and Mean Time to Acceptable highlight how equipment behaves after interventions. These aren’t abstract KPIs — they tell you whether production capacity is increasing, whether breakdowns are truly becoming less frequent, and whether corrective actions are swift enough to protect throughput. For plant managers, this immediately surfaces which assets are driving performance, and which are at risk of dragging it down.

But the value extends far beyond operations. Downtime avoided is quantified in hours and translated into financial terms, multiplying validated uptime by the real value of production per hour. A prevented conveyor stoppage, for example, isn’t logged as “just another fix” — it becomes a defensible dollar value in a CFO’s review.

From there, Enterprise Metrics layers in financial and sustainability outcomes. Energy savings (e.g., 15,346 kWh), emissions reductions (11 MTCO₂), and replacement cost avoidance provide sustainability leaders and finance executives with verifiable data they can carry directly into ESG scorecards and annual reports. The ROI gauge and savings breakdown turn maintenance outcomes into enterprise-level value, giving executives confidence that every intervention scales beyond the plant floor.

Finally, the Health Status view makes strategic alignment simple. Assets are categorized from “acceptable” to “unacceptable,” enabling leaders to direct resources toward the issues with the greatest enterprise impact. When combined with acknowledgment rates and repair cycle trends, organizations move away from firefighting and toward proactive, value-driven asset management.

The outcome is clear: when maintenance results are traced from the first intervention through to their financial and ESG impact, maintenance stops being a cost center and becomes a measurable driver of profitability, resilience, and sustainable growth.

In most organizations, these stories are split into silos: maintenance talks uptime, finance talks savings, sustainability talks emissions. Enterprise Metrics threads them together into a single business narrative: here’s the intervention, here’s the outcome, and here’s the enterprise impact.

Why This Matters — Tailored to Every Role

- Reliability engineers can prove their interventions are extending MTBR and speeding up recovery, giving them hard numbers to fine-tune maintenance plans.

- Plant managers can show downtime avoided in hours and dollars, turning reliability into a lever for production stability.

- Finance teams can validate real, justified ROI, not estimates, down to the source of each dollar saved.

- Sustainability leaders can link every kWh and MTCO₂ saved directly to maintenance activities, strengthening ESG reporting with live data.

- Executives can finally see maintenance as a business case: resilience, competitiveness and sustainability, all in one view.

The Future of Maintenance Intelligence

Industrial performance, cost control, and sustainability are converging. Future leaders will be those who can show exactly how an operational decision in one area delivers value in all three.

In a future with Enterprise AI, predictive maintenance data will feed capital planning. Energy and emissions results will be pulled directly into ESG disclosures. Asset health trends will shape market commitments.

With Enterprise Metrics, that future isn’t theoretical, it’s already in reach.

Want to see Enterprise Metrics in action? Get a Demo!

About the Author

Kareem Younis is Senior Product Development Manager at Nanoprecise, building cutting-edge solutions that turn asset-level insights into enterprise-wide impact.

With experience spanning engineering, automation, and strategy, from Deloitte Consulting to leading product and partnerships across North America, Kareem brings a practical, cross-functional lens to digital transformation in maintenance.

He holds an MBA in AI from Kellogg and a B.S. in Industrial & Systems Engineering from the University of Minnesota. His work centers on making maintenance data matters, operations, finance, and sustainability.