Effective Approaches for CO2 Emissions Reduction

Energy-Centric Maintenance for CO2 Emissions Reduction in Industries

Nearly 60% of the world’s electricity usage stems from motor-operated equipment, underscoring their significant role in monitoring machine health. Faults within these motors further elevate power consumption, operational expenses, and CO2 emissions and inflate overall lifecycle expenses. Surprisingly, energy costs contribute to over 90% of the lifecycle expenditure for motor-driven machinery, compared to minor expenses associated with motor procurement, upkeep, and installation, which collectively account for only 5-7% of the total lifecycle cost. Also, with unaddressed machine faults like this, the industry releases kilotons, and tons of CO2 back into the environment, which otherwise could have been easily curbed.

Energy-Centric Maintenance in CO2 emissions reduction

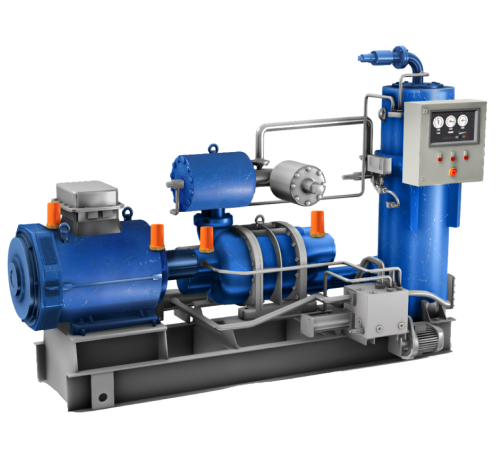

Meeting sustainability goals and complying with carbon emission regulations are essential for global industries. In achieving this, ECM technology is pivotal in C02 emissions monitor & reduction. Let’s take an example of a typical pump with an impeller that caused an imbalance, detected within two weeks of installing a wireless monitoring system. Still, it did not have a high enough vibration to cause concern and ran for two and a half years without any signs of catastrophic failure. As soon as the imbalance, a manufacturing defect, was removed, it decreased energy consumption by seven percent on a 250-horsepower pump. If this excessive power consumption had been detected two and a half years ago, it could have saved over $100,000 in lost energy and tons of kilotons of carbon being emitted. Regular equipment maintenance is required to ensure energy consumption is as consistent or optimized as possible, impacting global CO2 emissions reduction.

NrgMonitor by Nanoprecise for CO2 emissions monitoring

NrgMonitor, the energy-centric maintenance solution by Nanoprecise, is easily integrated into existing machine monitoring operations. It mainly focuses on providing industries with data and analytics crucial for C02 emissions monitoring, directly impacting CO2 emissions reduction if acted upon. The solution is easy to install and train, requiring only a short time to understand the equipment’s patterns. It achieves this by leveraging Industrial Internet of Things (IIoT)-based sensors, MachineDoctor, unique AI-powered software, and multiple physics applications to understand the degree of additional energy consumed by any faulty motor-driven machinery. It also provides immediate users with action steps to curb this wastage.

CO2 Emissions Monitoring with Real-Time Insights

An effortless synchronization of sensors and AI algorithms offering real-time insights empowers Industries, Energy Monitoring Managers, and Plant Managers with monitoring data like never before. The MachineDoctor sensor, powered by batteries, tracks six vital machine health indicators: Triaxial Vibration, Acoustic Emissions, Temperature, True RPM, Humidity, and Magnetic Flux. It effortlessly connects to the cloud for analysis via cellular networks or Wi-Fi, ensuring seamless data transmission. These sensors, coupled with the AI + Physics algorithms solution NrgMonitor, provide the date to reevaluate how energy consumption is monitored today. Also, the data collected through the process of CO2 emissions monitor is then used for prescriptive analysis to create strategies and

Conclusion

The merits of energy-centered Maintenance using NrgMonitor from Nanoprecise is too big to be explored. Users can expect the following advantages from using NrgMonitor from Nanoprecise.

- Energy consumption is reduced or, at the very least, optimized.

Manufacturing defects can be easily identified. - It helps to justify a much stronger ROI case, and the time to ROI is significantly reduced and valid for all equipment.

- It helps justify ROI, even if the machine has already gone down.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.