Pharmaceutical Temperature Monitoring: Preventing a $9 Mill Batch Loss

Customer Profile

A leading global pharmaceutical Contract Development and Manufacturing Organization (CDMO) aimed to increase equipment reliability and avoid costly disruptions at its peptide production facility in the United States.

As part of its commitment to product integrity and delivery assurance, the manufacturer needed a way to detect emerging equipment faults early.

In this highly sensitive environment, one piece of equipment underperforming could result in multi-million-dollar losses, missed delivery schedules, and reputational risk with global pharmaceutical clients.

Challenge

The facility faced significant risk from a centrifugal pump used to circulate a methanol/water mix through a reactor jacket—ensuring precise temperature control during drug synthesis. The pump had no redundancy, and any ongoing batches could not be transferred mid-process. With batches of products worth millions and no room for reactive maintenance, the CDMO needed a solution that could provide early and actionable insights into equipment health to avoid process disruptions.

Solution Deployed

Nanoprecise implemented its Energy-Centric Predictive Maintenance platform to provide continuous, real-time machine condition monitoring by employing the following key capabilities:

- Wireless sensors with 6-parameter machine condition monitoring (including temperature and humidity monitoring).

- Automated fault detection powered,

- Real-time vibration analysis with FFT analytics

- Early-stage fault alerts via cloud dashboard

- Seamless integration with maintenance planning

Assets Monitored

As part of the implementation, Nanoprecise deployed its solution across several key assets. These included:

- Distillate Pumps

- Swamp Coolers

- Exhaust Fans

- Agitators

- Various Compressors

- GL Filtration Dryers

Observation & Analysis

Nanoprecise sensors were installed on the centrifugal pump at:

- Motor Drive End (DE)

- Motor Non-Drive End (NDE)

- Pump Drive End (DE)

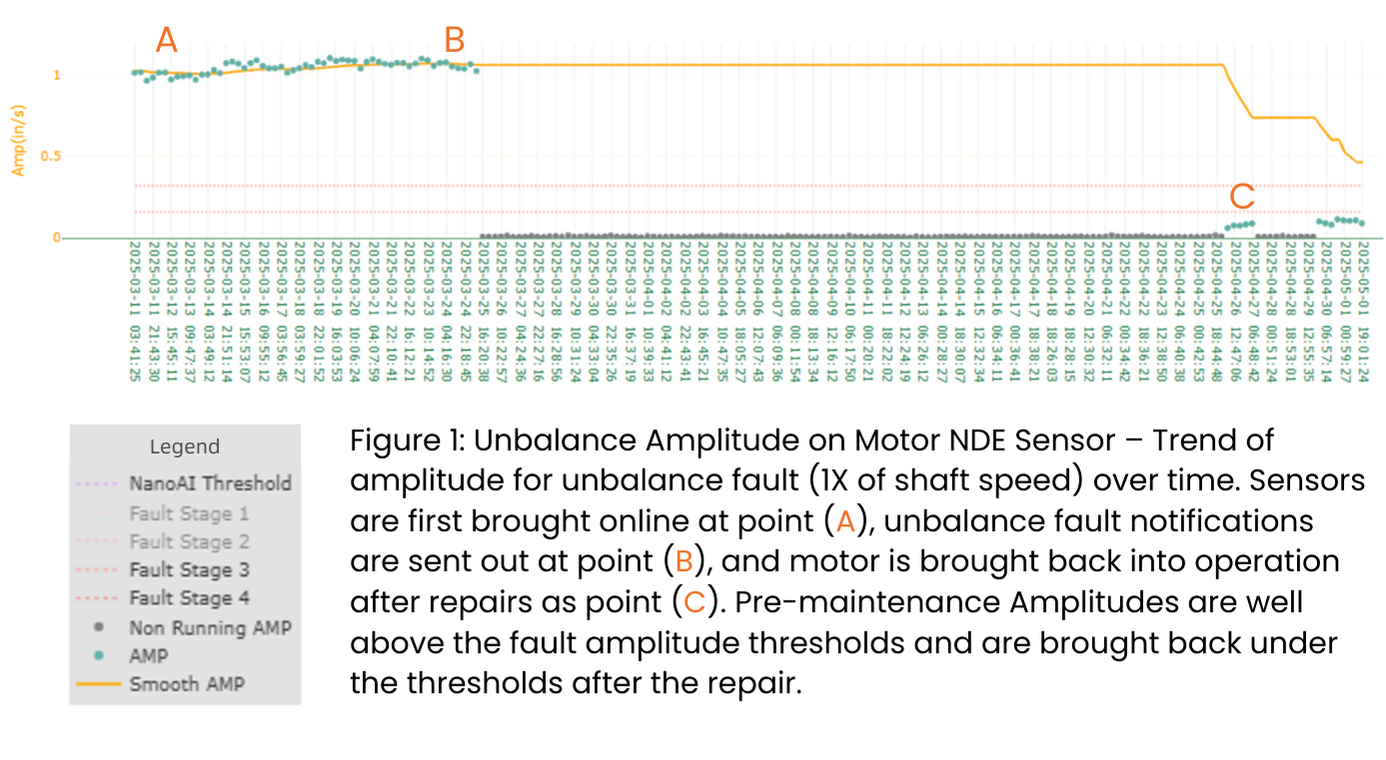

After a 14-day learning period, the system quickly detected Stage 4 faults at the motor ends and a Stage 3 unbalance on the pump side.

Vibration Analysis Summary

- Unbalance and Structural Looseness detected at multiple points.

- Fault frequencies exceeded thresholds.

- Dominant peaks matched 1× shaft speed—indicating severe unbalance.

- Cracked concrete base and loose/missing shims discovered on inspection.

- Vibration amplitudes at fault frequencies exceeded pre-established thresholds (Fig 1).

- Fault signature analysis showed dominant frequencies correlating with unbalance and base looseness

- Corrective actions were implemented during a planned maintenance window, avoiding disruption to the ongoing batch.

Corrective Actions Recommended by Nanoprecise:

- Replace damaged concrete base

- Secure loose bolts and replace missing shims

- Realign pump and motor

- Perform post-maintenance vibration verification

What Their Team Said

“The Nanoprecise team provided detailed explanations that helped us understand our maintenance needs around the pump. Thanks to their expertise we were able to mitigate the fault and extend the life of the equipment.”

Results & Impact

In less than 3 weeks after deployment, the pharmaceutical manufacturer reported the following:

- By taking corrective action, a $9M batch failure was prevented

- Emergency Repair Costs Avoided

- Equipment Lifespan Extended

- Operational Continuity Maintained

- Quick Time to Value with Fault Detected in under 3 Weeks

Nanoprecise’s energy-centered predictive maintenance solution enabled the facility to avoid catastrophic failure, perform targeted maintenance, and complete the batch without interruption.

Conclusion

In under three weeks, Nanoprecise’s predictive maintenance solution helped the pharmaceutical manufacturer detect critical equipment faults—preventing a $9 million batch loss. The real-time insights enabled targeted repairs during planned downtime, avoiding disruption, extending equipment life, and maintaining delivery schedules.

This rapid, data-driven intervention proved the value of predictive maintenance—delivering massive ROI and safeguarding both product and reputation. Get a demo.

Download the Full Case Study

Read the full story of this Nanoprecise Customer, and view all available data charts.