A Sustainable Approach to Predictive Maintenance

Energy-centric Predictive Maintenance is based on the principle that machines requiring maintenance or repairs consume more electricity.

With visibility into the energy consumption of a machine, reliability teams can prioritize their maintenance schedules to keep machines running, while reducing their environmental impact.

The Benefits of Energy Centered

Predictive Maintenance (ECPdM)

Avoiding Downtime on your Critical Assets

Regardless of the approach, at its heart Predictive Maintenance is about keeping your operations up and running. Faults are a lagging indicator, so by focusing on energy consumption, you can see fluctuations long before they grow to become more. Our Energy-Centric Predictive Maintenance solutions arm you and your team with the visibility and foresight to ensure continued production.

Driving Maintenance Efficiencies

Having an Energy Centered or Energy-Centric focus means that energy consumption is the key indicator for where to spend your maintenance efforts. Being able to see which equipment is consuming more energy due to a fault, creates a more efficient maintenance schedule that is effective at not only reducing downtime but also reducing operating costs and the organization’s carbon footprint as a whole.

Reduce Your Footprint With Each Machine

Avoiding downtime is great, ensuring your team is working efficiently is a bonus, but one of the biggest challenges is meeting your sustainability targets without significant investment. Energy-Centric Predictive Maintenance delivers the data you need to understand what is driving your emissions up and where to focus your efforts to keep them low.

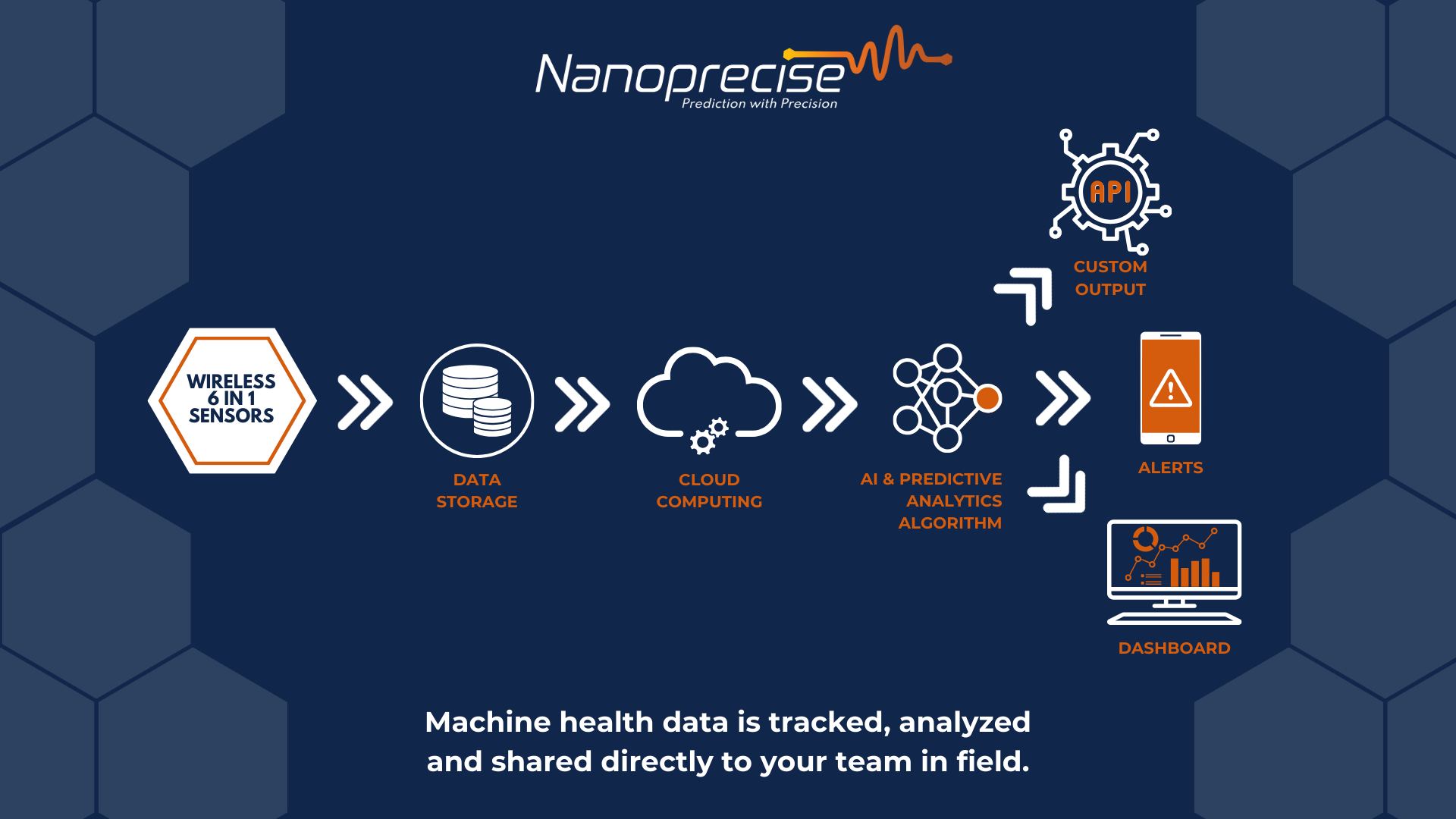

HOW ENERGY CENTERED PREDICTIVE MAINTENANCE WORKS

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.