“Predictive maintenance isn’t just about avoiding downtime – it’s about unlocking operational efficiency, sustainability, and smarter decision-making.“

As the Chief Revenue Officer of Nanoprecise, I’ve seen how manufacturers are shifting their focus beyond failure prevention to harnessing the full potential of predictive insights. From reducing energy waste and carbon emissions to improving maintenance planning and workforce efficiency, you need a solution that drives real, measurable value.

Predict. Prevent. Optimize.

Chief Revenue Officer, Nanoprecise

The promise of predictive maintenance (PdM) has always been clear: predicting potential equipment failures before they happen. But thanks to modern engineering design, where redundancy and fail safes are commonplace, catastrophic failures (leading to unplanned downtime) are less of a worry. Furthermore, manufacturing equipment reliability has also reached unprecedented levels. So, where does the true value of predictive maintenance lie?

At Nanoprecise, customers increasingly adopt our predictive maintenance solution not only for the elusive “what if,” but also for the tangible, everyday benefits that transform their operations. This article explores how Nanoprecise’s innovative predictive maintenance solution unlocks measurable value beyond preventing unplanned downtime.

Energy Savings

Reducing carbon emissions and greenhouse gases (GHG) has become a top priority for the manufacturing industry – a trend that is increasingly evident across various sectors. For instance, Deloitte’s analysis of investor reports from US industrial manufacturers reveals a growing emphasis on electrification and decarbonization. Mentions of “electrification” and “scope 1 emissions” have steadily risen through 2020 to 2024 from sectors such as engineering, construction, and mining and metals.

Several factors are driving this shift toward sustainability, including consumer demand, stricter regulations, and the visible impact of climate disruption. As a result, manufacturers are making strategic moves toward cleaner and greener operations, such as adopting renewable energy, using recyclable materials, and reducing emissions, packaging waste, and water consumption.

Nanoprecise’s Energy-Centered Maintenance (ECM) approach empowers customers to integrate sustainability into their operations and achieve such key environmental goals. By detecting excess energy consumption caused by faults well before they result in unplanned downtime, our solution drives both efficiency and sustainability. The added bonus? Substantial cost savings!

This is made possible through our patented 6-in-1 wireless sensor, MachineDoctor, which monitors six distinct machine health parameters. Unlike regular sensors that mostly monitor vibration and temperature, MachineDoctor also measures magnetic flux, providing unique insights. Machines operating inefficiently often exhibit abnormal magnetic flux, allowing us to identify and quantify excess energy consumption. With this visibility, reliability teams can conduct a cost-benefit analysis to figure out which machines are worth troubleshooting immediately, ensuring lower operating costs, and minimizing environmental impact.

Case Study: A leading water utility provider in the UK, responsible for managing over 40 reservoirs and 300+ water pumping stations, achieved precisely this by deploying Nanoprecise’s ECM solution. Our wireless sensors and analytics detected a resonance issue in a variable-speed pump, where increased vibration at a specific RPM range was significantly driving up energy consumption. With this critical insight, the utility company prioritized repairs, leading to reduced operational costs, decreased excess energy consumption, and enhanced reliability across over 25,000 km of water mains. Click here to read the full case study.

Better Predictive Maintenance Techniques

Maintenance and reliability may be two sides of the same coin, but budget constraints often force organizations to prioritize immediate fixes over long-term reliability. Nanoprecise’s predictive maintenance solution bridges this gap by making reliability both achievable and cost-effective for resource-constrained maintenance teams. The solution leverages wireless sensor technologies to identify potential failures early, minimizing costly emergency repairs and enabling the strategic

allocation of available resources. With advance warnings, maintenance leaders work with an increased planning horizon, being able to schedule tasks well in advance, and gaining the flexibility to handle unexpected challenges.

Additionally, greater insights into machine health inform maintenance frequency, empowering operators to extend maintenance intervals for certain machines and avoid costly over-maintenance. By monitoring key metrics like Mean Time Between Repairs (MTBR) or Mean Time Between Failures (MTBF), teams can take measures to extend operational intervals, reducing both labor and repair expenses.

This data-driven approach transforms maintenance from reactive to proactive. Maintenance becomes more than fixing what’s broken – it evolves into a strategy for enhancing reliability, extending equipment lifespan, and reducing total cost of ownership, all while cutting costs of energy wastage from faulty equipment. The result is a cultural shift toward proactive maintenance, where equipment health is continuously monitored, and issues are addressed before problems arise.

Streamlined Inventory Management

With an increased planning horizon, enabled by continuous condition monitoring and predictive insights, organizations can optimize spare parts inventory and streamline procurement. With greater visibility into equipment health and insights into root causes and known faults, maintenance teams can accurately forecast spare part requirements, ensuring they have only essential components on hand for planned maintenance or wear-and-tear replacements.

This prevents both overstocking and shortages, reducing carrying costs and minimizing emergency shipping expenses. By aligning inventory management with predictive maintenance data, companies can enhance operational efficiency while ensuring critical parts are available when needed.

Enhanced Safety with Predictive Maintenance Solutions

In 2023, private industry employers in the U.S. reported 2.36 million nonfatal workplace injuries, according to the stats released by the U.S. Department of Labor. This makes safety a top priority for plant and maintenance managers, as equipment failures are a major contributing factor to injuries in the manufacturing industry. Notably, the risk is particularly high during unplanned shutdowns or subsequent restarts – sometimes up to five times higher in certain industries – because the urgency to resume production can lead to hasty decisions without fully assessing potential hazards.

Nanoprecise tackles this critical issue by offering predictive maintenance solutions that alert maintenance teams to equipment faults before they result in unexpected failures. By delivering unmatched visibility into machine conditions, Nanoprecise empowers organizations to proactively address issues, thereby integrating safety into the core of maintenance and operations.

Case Study: At a Fortune 500 chemical plant, a critical cooling tower lacked adequate monitoring, compelling maintenance teams to perform unnecessary inspections in hazardous, hard-to-reach areas. Nanoprecise deployed its wireless sensors to continuously monitor the equipment, alerting the maintenance team to significant anomalies. This proactive approach not only prevented substantial financial losses but also enhanced worker safety by reducing exposure to dangerous conditions. Read the full case study here.

Improved Morale & Work-Life Balance

While new technologies can sometimes cause apprehension, Nanoprecise is designed to augment human effort rather than replace it. By automating tedious data analysis, our predictive maintenance solution empowers maintenance teams, freeing up experts to focus on complex, value-added tasks enhancing their expertise and reducing skill gaps. With an increased planning horizon and greater visibility into machine health, teams face fewer last-minute emergencies, reducing stress and eliminating guesswork. This shift from reactive to predictive maintenance allows maintenance & reliability supervisors, managers, and technicians to plan better, ensuring they can go home on time without unexpected weekend call-ins. As the industry grapples with retiring subject matter experts and struggles to attract younger talent, Nanoprecise helps build a digitally enabled workforce, improving retention, boosting productivity, and fostering a stronger organizational culture.

Effective Time Management with PdM

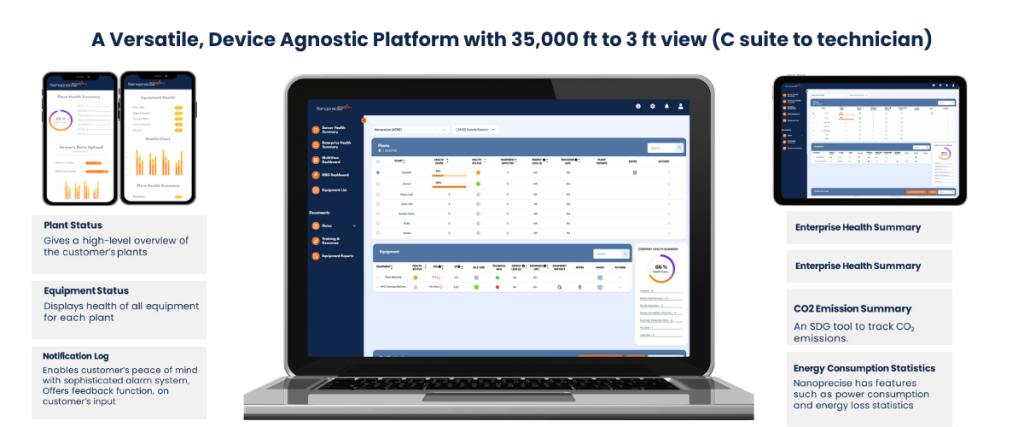

Nanoprecise’s predictive maintenance solution enhances effective time management by minimizing unplanned work orders and eliminating last-minute surprises. Acting as your single source of ground truth, it consolidates critical machine health data (captured from six key parameters) into a single dashboard, eliminating the need to monitor multiple systems. With actionable fault notifications that include recommended corrective actions, maintenance teams no longer need to speculate their next steps. Be it something like checking a motor mount to reduce transient resonance or inspecting vane pass based on acoustic and vibration analysis. This ensures that teams can hit the ground running, work faster, and operate smarter, maximizing efficiency and productivity.

Why do these value drivers matter?

As you have seen Nanoprecise’s energy-centered predictive maintenance solution is not just a tool for preventing downtime; it’s a powerful mechanism for enabling continuous cost savings and driving ongoing improvement across the organization. By delivering tangible value in areas such as energy savings, safety, workforce empowerment, and operational efficiency, Nanoprecise helps organizations move beyond reactive maintenance toward a future of proactive, data-driven reliability. With Nanoprecise, the promise of predictive maintenance evolves from a “what if” safety net into a “here’s why” strategy for infusing predictive analytics into daily operations.

At Nanoprecise, we are committed to helping our customers focus on delivering reliable solutions that drive real value. Click here to learn more about how we can support your operations and guide you in taking the first step toward unlocking true value.

About the Author

Brian Keith Richmond is an accomplished leader with over two decades of experience driving innovation, operational excellence, and revenue growth across diverse industries. As the Chief Revenue Officer at Nanoprecise Sci Corp, Brian leverages his expertise in AI-driven predictive maintenance and reliability solutions to deliver transformative results for clients worldwide.

With a distinguished career spanning technology, engineering, and leadership, Brian has held pivotal roles, including CEO of Richmonds Consulting Firm LLC and Head of Solution Development & Delivery at Augury. At Augury, he achieved a remarkable 160% ARR growth, streamlined sales cycles by 20%, and increased customer satisfaction and product adoption by 40%.

A U.S. Navy veteran with extensive experience as a Nuclear Power Plant Administrator, Brian has honed his skills in reliability engineering, team leadership, and process optimization. His ability to align strategic vision with operational execution has made him a trusted advisor and a driving force behind organizational success.

Brian is passionate about fostering innovation and empowering teams to unlock their potential. When not advancing cutting-edge solutions, he contributes to industry thought leadership, sharing insights on digital transformation and AI technology through conferences and podcasts.