Predictive Maintenance of

Transformers

Why is Predictive Maintenance of Transformers Essential?

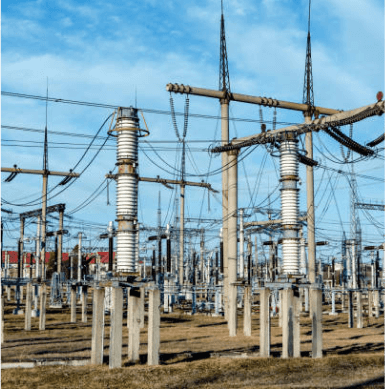

Transformers play a pivotal role in the smooth functioning of power distribution across industries, ensuring electricity is safely and continuously flowing. However, due to constant exposure to heavy electrical loads, temperature fluctuations, and various environmental factors, transformers are susceptible to wear and tear, leading to potential failures. Predictive maintenance is a preventive measure that detects emerging issues early, helps maintain uninterrupted operations, and avoids expensive breakdowns.

The Impact of Predictive Maintenance of Transformers

Early Detection of Faults: Monitoring key parameters such as acoustic emissions, temperature, and vibration allows the detection of early warning signs like partial discharge or winding deformation. These indicators help prevent larger problems before they develop and are ideal when it comes to Predictive Maintenance of Transformers

Reduction in Downtime:

Transformers that fail unexpectedly can disrupt operations and cause production delays. Predictive Maintenance of Transformers identifies potential issues before they occur, making it possible to organize scheduled maintenance and avoid costly unplanned downtime.

Extension of Transformer Life:

Consistent monitoring through Ai Based Predictive Maintenance reduces strain and stress on the components of the transformer, helping in avoiding wear and prolonging the lifespan of the equipment and transformer in total.

Enhanced Safety of equipment and plant personal:

Transformers operate under very high voltages, that can pose significant risks in case of sudden failures. Predictive Maintenance of Transformers greatly reduces the likelihood of such failures and improves the overall safety in the workplace.

Cost Savings:

By preventing major faults and reducing emergency repairs, predictive maintenance helps lower operational costs. It allows for more efficient use of the maintenance budget, focusing resources on critical issues rather than reactive fixes.

Improved Reliability in Critical Applications:

Predictive Maintenance of Transformers is especially valuable for transformers in critical environments such as hospitals, data centres, and manufacturing plants, where uninterrupted power supply is of utmost importance.

Introducing TransformerLF for Effective Predictive Maintenance:

TransformerLF by Nanoprecise empowers organizations to shift from reactive to proactive maintenance. With AI-driven insights, this solution continuously monitors transformer health before they can impact operations. Tailored to the specific needs of each plant, TransformerLF provides essential alerts to ensure smooth operation.

Key Features of TransformerLF from Nanoprecise

Multi-Parameter Monitoring:

Tracks crucial data points such as acoustic emissions (up to 160 kHz), vibration, temperature, humidity, and magnetic flux, ensuring comprehensive fault detection in Predictive Maintenance of Transformers

Advanced AI for Early Fault Detection:

The predictive AI technology is designed to detect issues like partial discharge and winding deformation, helping to prevent unexpected failures.

Seamless & Secure Setup:

With quick installation and robust data encryption, TransformerLF can be deployed easily, providing high-level security without complicated configurations.

Real-Time Fault Insights via MachineDoctor:

The Machine Doctor feature delivers precise, actionable alerts, pinpointing fault locations, types, and the remaining useful life of transformer components, enabling timely intervention.

Detailed Insights and Greater Control with MachineDoctor

MachineDoctor elevates Predictive Maintenance of Transformers by offering clear, actionable insights into specific components under stress, the nature of the fault, and the expected time to failure, ensuring that maintenance teams can respond promptly and effectively.

Remote Monitoring: Anytime, Anywhere

TransformerLF’s mobile and web applications provide real-time access to key transformer health metrics and immediate alerts, no matter the location. This remote monitoring feature, powered by AI and IIoT, ensures continuous oversight, offering peace of mind without the need for constant on-site checks.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.