Nanoprecise Prevents Downtime in Fiberglass Curing Process with Early Detection of Fan Faults

Customer Profile

A leading fiberglass insulation manufacturer in the Middle East sought to improve equipment reliability and avoid production disruptions through advanced condition monitoring.

With exports to over 30 countries and applications across construction, HVAC, and Oil & Gas, the company’s operations depend on uninterrupted curing processes—where precision temperature control and airflow are critical to maintaining product quality.

During curing, ACC circulation fans play a key role in removing moist air and particulates. Even minor underperformance at this stage can compromise product integrity and lead to costly downtime.

Challenge

The manufacturer faced increasing risk of mechanical issues in critical curing equipment, particularly in circulation fans, where vibration-related faults could lead to unplanned shutdowns, scrap material, and missed deliveries.

Solution Deployed

Nanoprecise implemented its Energy-Centric Predictive Maintenance platform to enable continuous, real-time monitoring of mechanical health. The system provided advanced diagnostics such as:

- Real-time vibration + FFT analytics

- Early fault detection algorithms

- Cloud dashboard for visibility

- Automated alerting to the maintenance team

Assets Monitored

As part of the implementation, Nanoprecise deployed its predictive maintenance solution across several key assets critical to the curing process and overall plant operations. These included:

- Hammer Mill Crushers

- Blower Fans

- Forming Suction Fans

- Chopper Motors

- Venturi Pumps

- Cooling Towers

Observation & Analysis

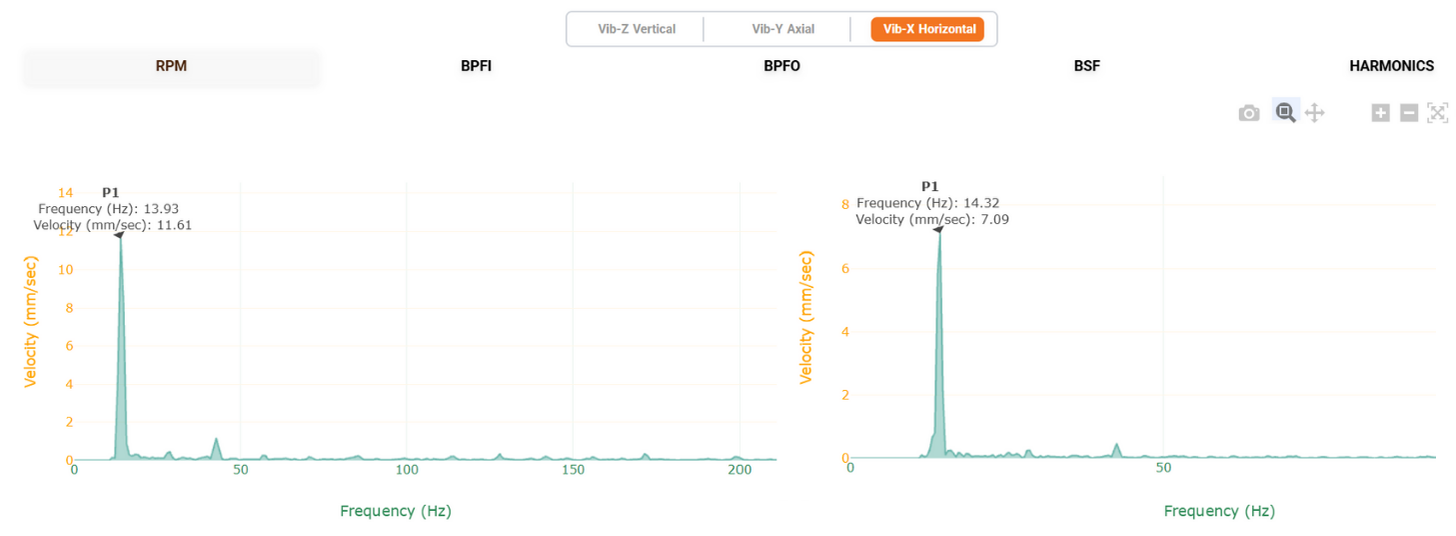

Vibration Analysis Summary:

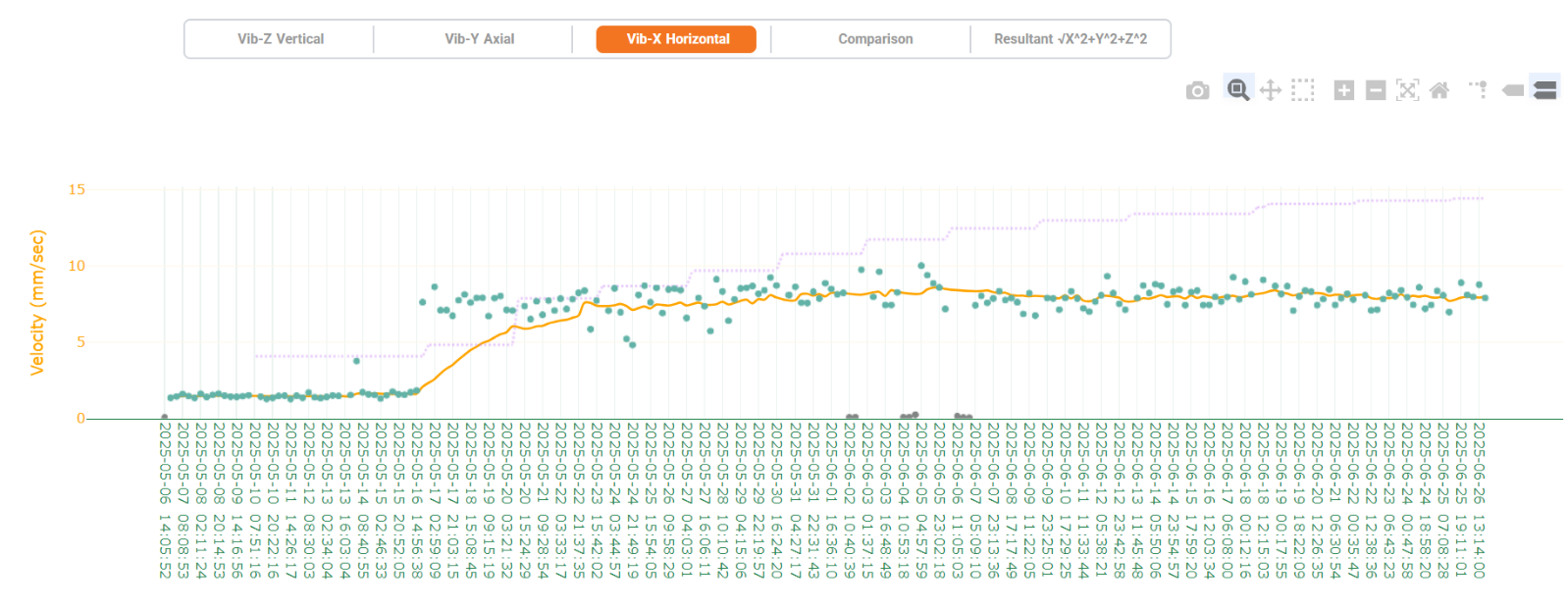

- RMS Velocity: Increasing trend at motor and fan bearings

- FFT Spectrum:

- Dominant peak at 14.3 Hz (1× RPM) with amplitude of 11.6 mm/s

- Secondary peaks at 28.2 Hz (2×) and 42.5 Hz (3×)—consistent with rotor unbalance

- Indications of possible misalignment between motor and fan shaft

- Want to see the dashboard? View our video walkthrough.

Corrective Actions Recommended by Nanoprecise:

- Inspect and clean fan impeller to remove dust/debris

- If vibration persists, schedule dynamic balancing

- Check coupling condition and reassess shaft alignment

- Perform follow-up vibration reassessment to confirm resolution

Results and Impact

- Unplanned Downtime Prevented

- Equipment Lifespan Extended

- Improved Operational Visibility

Nanoprecise enabled early fault detection, allowing the maintenance team to resolve the issue during a planned maintenance window, avoiding emergency repairs and production loss. View our dashboard walkthrough.

By intervening early, the team prevented further stress on the fan, improving its longevity and performance. Greater visibility into mechanical health also allowed the team to better allocate maintenance resources—reducing pressure on personnel and improving long-term planning.

Summary

In temperature-sensitive operations like fiberglass curing, equipment health directly impacts product quality, delivery schedules, and plant efficiency. Nanoprecise’s predictive maintenance solution helped this manufacturer move from reactive firefighting to proactive reliability, avoiding costly disruptions and extending asset life

Want to see it work for you? Get your demo!