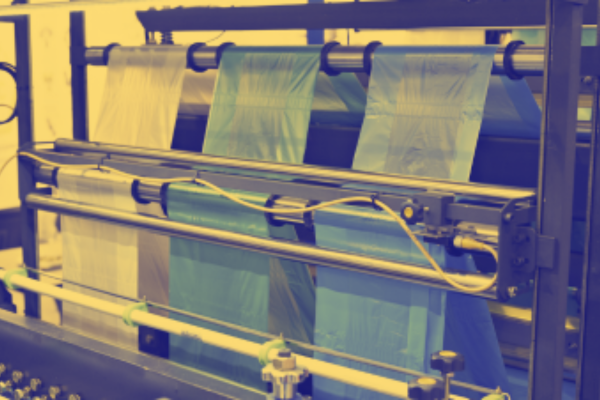

CPG Manufacturing

In Consumer Packaged Goods (CPG) Manufacturing, consumer preferences are constantly evolving, and manufacturing processes must adapt quickly to keep up. Recent trends towards sustainability call for not just sustainable products, but also sustainable manufacturing processes.

With increasing demand for innovative CPG products, manufacturers are under pressure to deliver both high mix and high volume production. This growing demand places significant strain on existing machinery and production infrastructure.

The good news is Nanoprecise’s Energy-Centered Predictive Maintenance solutions are perfect for the CPG industry in mitigating these challenges!

Consumer Package Goods Manufacturing Challenges

High Mix, High Volume Production

Consumer preferences are changing faster then ever. CPG manufacturers are under more pressure than ever to churn out new SKUs, putting more strain on machinery often already running at full capacity.

Regulations

Products must meet the regulatory requirements for CPG in both the country that manufacturers them AND the country that imports them. If a product fails to meet these standards, there can be severe financial penalties, major product recall or irrevocable damage to your reputation. When machines are not operating properly, the product is less likely to meet regulatory production standards.

Supply Chain Unpredictability

Not delivering products on time can create tension with vendors and cause brands to loose shelf space. While some supply chain factors are out of your control, manufacturing is not, and unplanned downtime is preventable.

Sustainability & GHG Reduction

Consumers are demanding that their products be more sustainable, but certain products can only go so far. Companies must take this additional action and consider their emissions, especially as pertains to SCOPE 1 & 2.

Trusted By Your Peers

See it Work For You

Our cutting-edge predictive maintenance solutions are tailored to address the unique challenges faced in CPG Manufacturing.

See how we seamlessly integrate with your operations to help you eliminate unplanned downtime in your CPG plants, reduce carbon emissions and improve your overall operational efficiency.