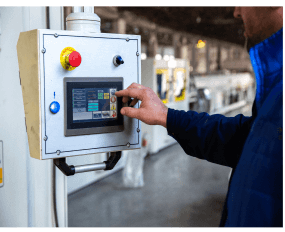

Monitor energy and efficiency

Unlock the power of real-time energy monitoring that can transform the industry

Why Monitoring Energy Consumption and Efficiency is Crucial for Industries

Energy monitoring ensures compliance with local and international regulations regarding energy consumption and emissions. Detailed and accurate reporting and data analysis help in meeting these standards, avoiding penalties, and gaining certifications that can be beneficial for the business. In fact, industries are under continuous pressure to reduce carbon emission. When industries monitor energy and efficiency, wastage is reduced and a step is taken towards environmental sustainability.

Again, real-time monitoring helps in optimizing the performance of machines and processes which results in reduced downtime and enhanced productivity. Energy takes up a huge part of the operating expense in an industry. Hence, it is essential to monitor energy and efficiency closely to identify the inefficiencies and implement corrective measures for that. Reduced energy wastage results in cost saving that can eventually help to increase profit margins.

5 benefits of monitoring energy in Industries

Operational efficiency and sustainability in industries largely depends upon implementing energy monitoring. It not only adds value in terms of regulatory compliance but also helps with strategic decision related to industrial operation. Hence, when industries monitor energy and efficiency, it benefits them in several ways.

- Industries monitor energy and efficiency to optimize the performance of equipment. Through preventive maintenance it can detect anomalies and reduce downtime.

- By ensuring that equipment usage is optimized and energy is used efficiently within the industry setting, by adjusting consumption patterns, the overall cost can be reduced.

- Strategic decisions are always data-driven. Hence, continuous monitoring helps to improve.

- Industries can reduce their carbon emissions and environmental impact by efficiently using energy.

- When industries monitor energy and efficiency, they contribute to sustainability goals and regulatory compliance.

NrgMontitor key features

It offers real-time monitoring.

It is powered by advanced analytics to identify inefficiencies.

It optimizes energy usage.

It is a cost efficient and scalable solution.

Its agile integration capabilities ensure seamless collaboration with existing systems.

NrgMonitor Differentiators

Nanoprecise focus on optimizing industrial operations by addressing different aspects of industrial efficiency. It specializes in an energy-centred maintenance solution known as NrgMonitor.NrgMonitor excels with comprehensive energy monitoring, AI-driven insights, seamless integration, and an intuitive dashboard for easy data interpretation

Nanoprecise specializes in predictive maintenance and condition monitoring with the help of advanced sensors and AI-based technologies. Through precision sensors and technology-based solutions, Nanoprecise reduces the chance of equipment failure and optimizes the aspect of maintenance and reliability.

Nanoprecise offers both prescriptive maintenance solution as well as energy-centred maintenance solution. Its energy-centric maintenance approach which is NrgMonitor solution is different from its traditional RCM counterpart. NrgMonitor monitor energy and efficiency and offers energy management solutions based on real-time energy consumption data by using IoT sensors. It focuses on offering a complete overview of the total energy consumed while RCM is limited to identifying faults within the machines.

Through AI-driven analytics, NrgMonitor identifies energy saving opportunities to customize solutions. It can be easily integrated into existing machine monitoring operations and has an intuitive dashboard to understand and interpret data efficiently.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.