Case Studies

Know how we offer peace of mind to our customers with help of AI based Predictive Maintenance.

Cement Equipment Condition Monitoring | Case Study

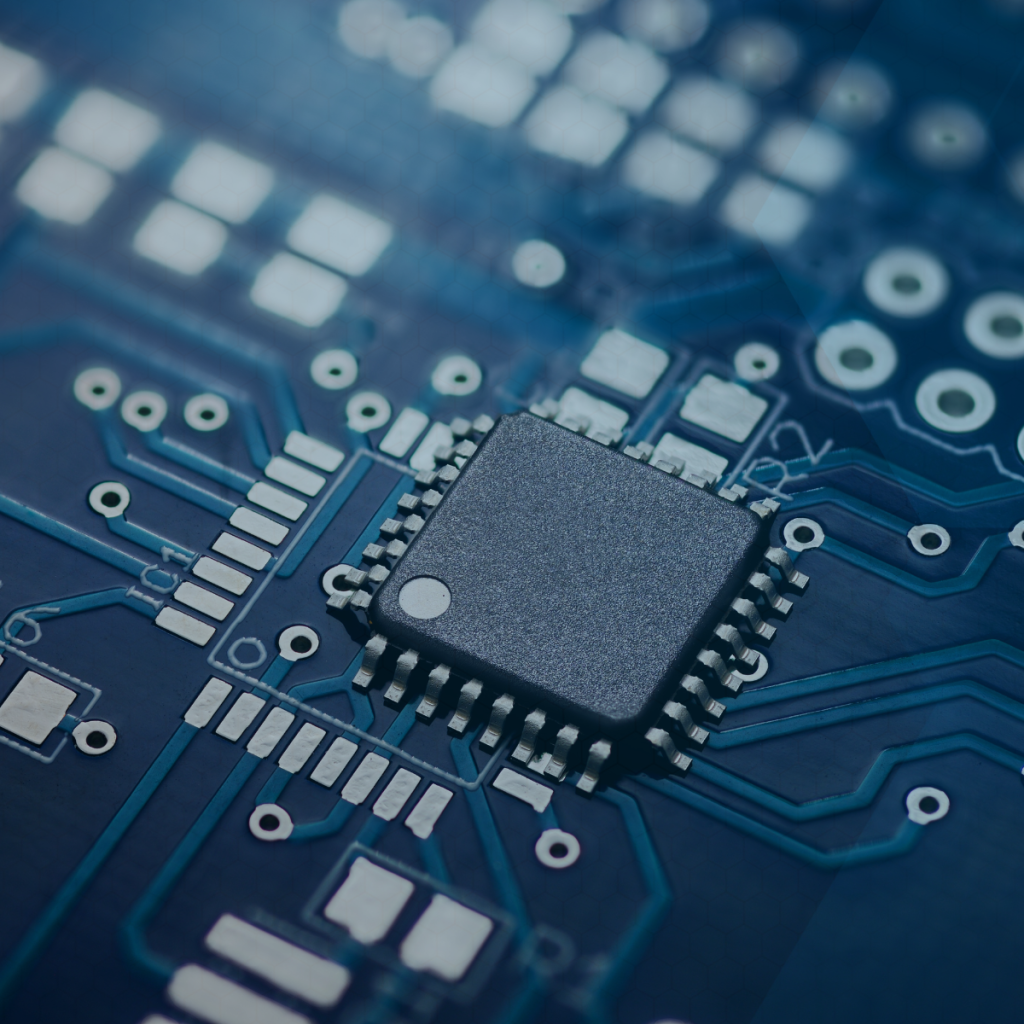

See how predictive maintenance is used in the semiconductor manufacturing process for faut detection and prevention.

Enabling Predictive Maintenance in Semiconductor Manufacturing

See how predictive maintenance is used in the semiconductor manufacturing process for faut detection and prevention.

Water Treatment Plant : Preventing $200K Equipment Failure on a Dewatering Centrifuge

A water treatment plant used continuous vibration monitoring to detect a late-stage fault on a dewatering centrifuge. Early detection avoided…

Airport Ground Support Equipment PdM: Fault Detection 6 Weeks Before Failure

One international Canadian Airport selected Nanoprecise to increase reliability of their Ground Support Equipment. Within 1 week, a bearing fault…

Nanoprecise Detects Boiler Fan Motor Fault for Pharmaceutical Giant

Nanoprecise partnered with a global pharmaceutical manufacturer to monitor and maintain the health of critical equipment in production and…

Nanoprecise Helps Automotive Plant Prevent Blower Failures With Blower Vibration Analysis

Learn how this automaker achieve daily energy savings of $537, and CO₂ emissions reduction by 2.1 metric tons!

Nanoprecise Prevents Downtime in Fiberglass Curing Process with Early Detection of Fan Faults

Discover how a fiberglass insulation manufacturer prevented unplanned downtime by enabling early fault detection in critical assets like blower fans…

Pharmaceutical Temperature Monitoring & Predictive Maintenance: Saving a $9 Million Batch.

Discover how Nanoprecise’s PdM saved a $9M batch from spoilage by identifying a pump fault tied to pharmaceutical temperature monitoring.

Predictive Maintenance Food and Beverage: Preventing Downtime on Dairy Processing Equipment

Learn how a leading dairy producer avoided hours of downtime by integrating a predictive maintenance solution for food and beverage…

Predictive Maintenance in Pharmaceutical: Preventing Downtime & Excess Energy Consumption

Learn how a leading pharma giant was able to prevent downtime, while saving upwards of $50,000 in energy costs per…

Sustainable Biofuel Production: Preventing 3 Separate Downtime Instances and a Loss of $18,000

Learn how energy-centered PdM helped a biofuel producer prevent three separate downtime incidents through early fault detection and diagnosis.

Predictive Maintenance in Oil & Gas: Identifying a $625,000 Failure in Advance

Learn how an oil and gas company identified a $625,000 failure in advance using Energy-Centric Predictive Maintenance.