Explore strategies to overcome common obstacles in scaling IIoT projects and achieve successful digital transformation

Pilot purgatory is the terrifying place where Digitization or Industry 4.0 projects go to die. It’s when companies pour resources into a project that doesn’t go anywhere after an initial small deployment.

The increased demand for goods and services in the age of globalization has put immense pressure on manufacturers and producers to increase their productivity and maximize their revenues. However, there is a limit to which machine components can be stretched before they inevitably fail, thereby causing huge production losses and significantly affecting the bottom-line of a business.

The advent of technology has allowed manufacturers and operators to solve this problem with technologies such as Industrial IoT, AI, and Cloud computing, which allows for real-time monitoring of the health & performance of equipment components, and predict failures, thereby enabling them to maximize their equipment uptime and keep the production/operations running.

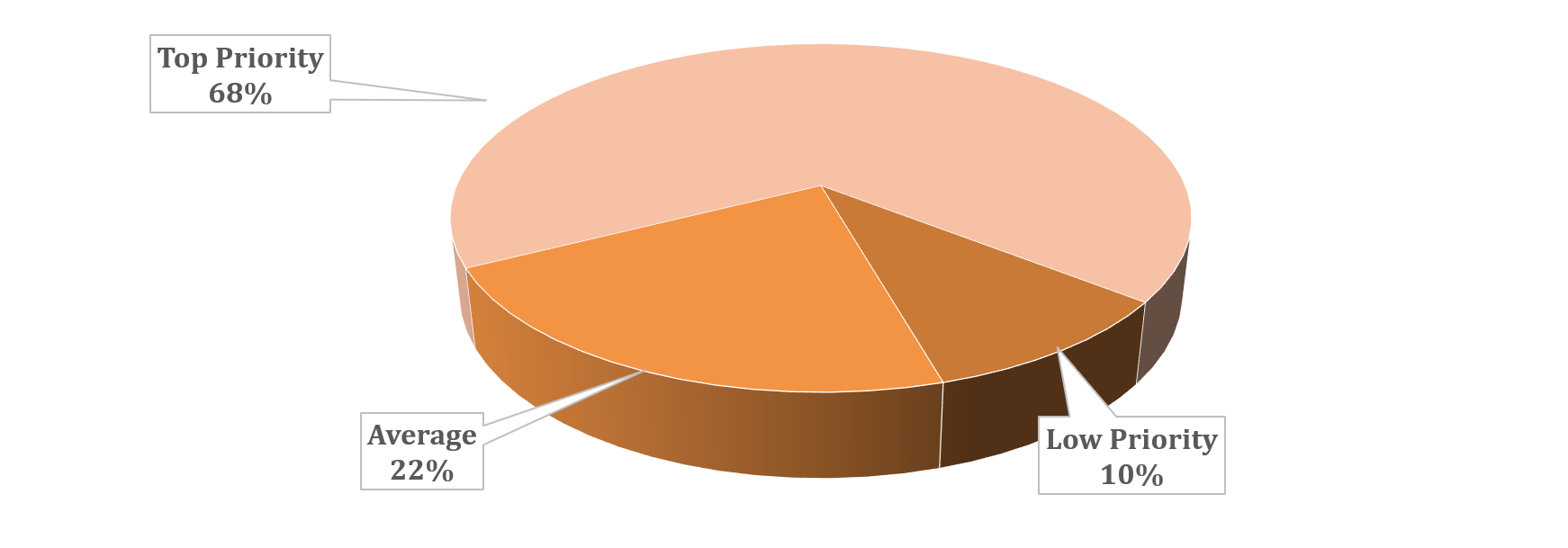

Organizations have turned to Digital transformation initiatives such as the deployment of IIoT across their manufacturing units to help them maximize the uptime of their equipment and thereby keep up their production levels. Most manufacturing companies consider Digital Manufacturing a top priority1.

However, many global manufacturing companies have seen stagnation in their digital transformation activities. Despite their increased interest and enthusiasm, no meaningful benefits are visible in their bottom-line. Manufacturers find themselves sinking into pilot purgatory with Industrial IoT deployments that fail to scale.

Pilot Purgatory

Pilot purgatory is where digitization and Industry 4.0 projects stall indefinitely, never progressing beyond the initial small-scale deployment. It’s a costly limbo where companies invest resources into pilots that fail to scale, ultimately leading to abandoned initiatives and lost opportunities.

Many of us might have heard about how hard it is to scale an IIoT project, and with all the different variables involved, it is easy to find ourselves stuck in pilot purgatory with no end in sight. In order to avoid pilot purgatory, it is essential for digital teams and maintenance operators to look at how to avoid this early in the pilot stage. There are so many things that could go wrong in an IIoT project that the likelihood of getting stuck somewhere can be pretty high.

Why Projects Go to Pilot Purgatory

There are a few main reasons why projects end up in pilot purgatory.

- Limited resources

This is one of the biggest contributors that drive IIoT projects into a pilot purgatory. IIoT projects can be complicated and can take a long time to come to fruition. Digital teams might have something up and running on the backend, but deploying the actual solution out there can be incredibly costly and time-consuming.

- Conflicting requirements

When everyone on the team is pulling in one direction and someone else is pulling the other way, companies inevitably end up somewhere in the middle of nowhere. When this happens, IIoT projects can get stuck. Digital transformation teams could have the best ideas and a solid plan, but without buy-in from everyone else involved, they are not going to get very far. When it comes to IIoT projects, conflicting requirements often develop as a result of trying to achieve too much with a project. It’s important to make sure that everyone involved in the project is on the same page and that a smaller number of priorities have been established so that the project does not experience scope creep. If the scope and the timeline of the project is not clearly defined, there are high chances that the project may not meet the deadlines and achieve a clear outcome that can be evaluated for value and effectiveness.

- Data Silos

Automation technologies use tools such as IIoT and Artificial Intelligence to build models that help solve complex business problems. All of these tools need data to learn and much of this data would come from different sources. Eliminating data silos to streamline data collection for common enterprise use requires a conscious effort that aims to bring together multiple teams from the shop floor as well as the top floor.

- Focus and Build/Buy Decisions

Even with the availability of good data, building models using tools such as IoT and AI can be a cumbersome task to undertake in-house. Building a model that accurately tracks even the smallest detail and modulating everchanging variables automatically can itself be a complex task to achieve, let alone making it scalable. The challenge of dedicating immense resources towards achieving such a feat is why most of the enterprises turn to solution providers with expertise in machine operations and condition monitoring. Where an enterprise has core expertise should not be outsourced but teams should be careful to avoid building up expertise in areas that could be purchased as a product or service already. For example, a pharmaceutical production firm should likely build core expertise around proprietary processes that only they have a true understanding of. Conversely, best in class predictive maintenance technologies are not their core expertise and should likely be outsourced/ purchased.

- Disconnected Stakeholders

Another reason why projects go to pilot purgatory is disconnected stakeholders. It’s important to make sure that everyone is on the same page with clear evaluation criteria. Communication is key to an IoT project, but it’s also the most difficult part. Keeping all the stakeholders involved in the project on the same page can be tricky when there are many different people involved from different departments. Teams could have the best ideas and a solid plan, but it may not go very far unless it is ensured that everyone else is on the same page. When it comes to IoT projects, bringing cohesion amongst disconnected stakeholders often come down to one thing: communication. It’s important to make sure that everyone is communicating with one another and that there is a clear chain of command. When everyone is on the same page regarding who is leading the project and who is responsible for what, IoT projects can go much more smoothly.

- Change Management

While it is important to mitigate the disconnect between teams & stakeholders, it is also essential to understand that IIoT projects are essentially a people business. It is observed that a common hurdle to digitalization efforts is the lack of conviction and trust amongst the workforce, who may believe that the transition to this targeted change may not be in the best interests of the organization. At times, there also exists a disconnect of the engineers & technicians on shop floor from the decision-making process, which may leave certain voices unheard leading to resistance. Moreover, the resistance to change may also stem from the fear of the unknown.

How to Avoid Pilot Purgatory

Despite a strong push for digital transformation from senior leadership, many initiatives struggle to move beyond the pilot phase. Common roadblocks include lack of stakeholder engagement, unclear objectives, undefined success metrics, financial constraints, employee resistance, and capability gaps.

As a result, pilots often fail to demonstrate value, getting stuck in “pilot purgatory” without a clear path forward. While IIoT projects can face various challenges, organizations can avoid stagnation and drive successful scaling by adopting the right strategies. The most effective approach is to bypass traditional pilot programs in favor of a Minimum Viable Product (MVP) strategy. This method enables companies to deploy a functional version of the solution across a broader scope, allowing the technology to showcase its value more effectively. Additionally, ensuring that teams have the necessary resources, well-defined goals, and a shared understanding of success further strengthens the chances of a successful IIoT implementation.

Some important aspects to ensure the successful scaling of IIoT projects are detailed below:

- Establish Goals

Establishing clear business goals and metrics is essential to prove the value of IIoT and other technologies. This could be total unplanned downtime prevented, energy savings, the overall equipment effectiveness or any number of measurable metrics. It is very important to identify the problem that needs to be solved with technology, and solving it will prove the value of the technology to the decision-makers, thereby enabling faster scaling. It is imperative that stakeholders look at pilots from a long-term perspective to gain a competitive advantage and not as an immediate fix.

- Determine Value Creation Metrics

The cost of implementing a solution can only be justified if the outcome is significant & measurable. It is essential to determine the measurable metrics for pilots that allow decision makers to see the value a particular technology will add to the business. Implementation of digital technologies such as IIoT should focus on business outcomes and the delivery of financial impacts, rather than functional benefits. This approach enables organizations to evaluate the immediate benefits of the technology and pursue digital transformation initiatives that are congruent with its business strategies and corporate goals. At the same time, the number of metrics should be limited and prioritized to avoid overcomplicating a project evaluation.

- Integrated Decision making

While IIoT projects are all about technology and digital transformation, the human element has a critical role to play in bringing it to fruition. While technology can assist with business change, this cannot happen without the buy-in from operational teams and a culture that is open to change and that can support the inevitable wrinkles of implementation without backing away at the first sign of struggle. So, it is essential to bring the stakeholders from various departments on-board the decision-making process. It may also help to establish periodic reviews by the leadership teams and communicating the progress and achievements to the stakeholders so as to showcase the value creation opportunities with new technologies.

In the case of small-scale pilots that are implemented with the goal of scaling across multiple plants and geographies, creating a common platform for all stakeholders from across plants, functions, and geographic locations to support and connect may help consolidate the efforts without repeating the steps at each level.

- Change Management

Employees may be reluctant to try new things due to a number of reasons. However, modern businesses must adapt to change their old ways in the current landscape, which makes it essential to approach change management in a strategic way. Organizations can move towards adopting the new business practices by following the best practices.

Driving the change from the top management is a significant step as it involves the upheaval of a long-standing culture in the organization. The senior leadership has the capability to ensure that each step is directed towards achieving the organizational goal.

Clear communication is also an essential component to ensure that the employees embrace change. The benefit of the technology should be communicated clearly to all stakeholders and any doubts or queries should be cleared to alleviate their fears & concerns, thereby bringing everyone on the same page.

All said and done, change management looks different for different organizations, and it is crucial for businesses to understand that change does not have a specific beginning and ending, but is rather an ongoing process.

- Bridge the capability gap

Building the capabilities of the employees is essential to addressing the challenges of digital transformation. Organizations should focus on empowering the in-house teams by way of internal training, partnerships with external contractors, collaboration with academic institutions, or hiring new talent.

- Leveraging Partnerships

Although there is a need for having a robust technology knowledge base in-house, it is to be noted that companies do not need to have everything in-house. Navigating complex landscape of technology stacks is a time-consuming endeavour that soaks up a lot of resources. To avoid spiralling into an abyss, manufacturers can seek to work with solution providers with functional expertise.

Technology deployments can be outsourced to experienced solutions providers, to save time & resources. They also play a key role in helping organizations shift from the conventional way of working to a renewed one aided by technology. Their expertise will be key to gaining in-depth knowledge and insights into the workings of the new technologies. Moreover, a strong partnership can smoothen the learning curve for operators.

Partnerships with solution providers who are skilled at deploying IIoT solutions at scale will help to create strategic roadmaps that will help to move from pilots to scaling faster.

- Learn from Mistakes

While organizations may start IIoT projects with good intentions & practices, no organization is immune to mistakes and failures. Organizations can learn from failed / stalled projects and apply the learnings from them to accelerate their progress in the next phase. It would be wise to collect data from each step of the way so that teams can use it to evaluate their steps and amend any mistakes/errors in the future.

- Achieving Scale

To successfully scale, it’s crucial to ensure adequate asset coverage from the outset. Every decision should be made with scalability in mind, treating the project as a large-scale initiative from day one. This means evaluating its business impact early and ensuring that key elements – technology stack, data collection, analysis, storage, transmission, privacy, and security – are designed to grow with the organization. Identifying the most suitable use cases and aligning them with the internal ecosystem helps prevent conflicts and accelerates scaling efforts.

Conclusion

Digital technologies offer immense value and have the potential to revolutionize manufacturing operations. Transitioning from traditional methods to a fully integrated digital approach has become a top priority for manufacturers worldwide. By adopting a holistic strategy for IIoT deployment and focusing on key success factors, manufacturers can accelerate technology adoption and achieve meaningful outcomes in a short time frame.