Choosing predictive maintenance software for cement plants starts with identifying your highest-cost failure points and mapping sensors to their real failure modes. Look for solutions that combine vibration and temperature monitoring with AI insights that explain why an asset is at risk. The best platforms go beyond alerts, delivering actionable guidance that integrates with your CMMS. Ease of installation, multi-variable sensors like Machine Doctor, secure connectivity and repair savings modelling should guide your evaluation.

TLDR: Choose predictive maintenance software that fits your cement plant’s highest-cost assets and aligns sensors to real failure modes.

Prioritize solutions with:

- Asset prioritization: Focus on your most critical assets — rotary kilns, ball mills, roller mills, crushers and main conveyors — based on downtime cost, safety risk and spare-part lead times.

- Sensor alignment: Select vibration, temperature and electrical monitoring aligned to specific failure modes and site conditions or consider a multivariate sensor solution.

- AI anomaly detection: Require explainable AI that quantifies detection lead time, highlights root cause evidence and delivers next steps to save on resources.

- Integrations and security: Confirm SCADA and CMMS connectivity (OPC UA, Modbus, MQTT, APIs) and enterprise-grade security compliance.

- ROI clarity: Model downtime, MTTR and parts savings using a repair savings calculator and validate cost of ownership before scaling.

Finding the Best Predictive Maintenance Solutions for Cement Industry Equipment

Choosing the best predictive maintenance software or integrated solution for cement plants determines whether your operation spends time and budget reacting to kiln and mill stoppages or executing predictable, scheduled work. A well-chosen system reduces emergency parts orders, uses AI-driven anomaly detection to surface early risk, and delivers condition intelligence (prescriptive guidence) that lowers unplanned downtime and maintenance costs.

This article provides a compact evaluation framework to assess your plant’s needs, prioritize assets and select a solution that delivers measurable ROI quickly and scales cleanly across lines and sites.

1. Start with a Clear Asset & Failure-Mode Assessment

Focus first on assets where a single failure carries the highest operational impact. In most cement plants, this includes rotary kilns, ball mills, roller mills, primary crushers and main conveyors.

Document dominant failure modes such as:

- Bearing, gearbox and liner wear in ball and roller mills

- Gearbox failures in crushers

- Splice, idler and belt faults on conveyors

Define measurable KPIs before deployment begins. Typical targets include percent reduction in unplanned downtime, MTTR improvement, validated predictive alerts and parts consumption reduction. Record numeric baselines so improvement can be measured objectively.

Align operations, maintenance, reliability and IT early. Clarify who owns SCADA access, who manages CMMS workflows and who responds to alerts. Assign a single accountable owner to ensure execution stays coordinated.

Prioritize platforms that support cement-specific workflows and translate AI anomaly detection directly into maintenance actions rather than isolated alerts.

2. Prioritize Sensors Suitable for Cement Factory Machinery

Choose sensors that detect the failure modes you identified and can withstand cement plant conditions, including heat, dust and constant vibration.

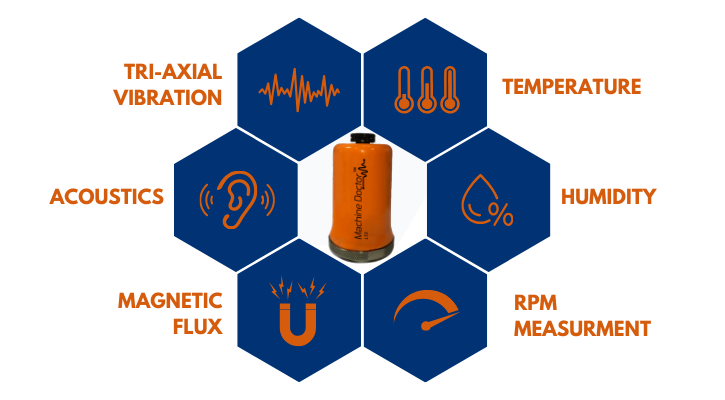

For critical equipment, like rotary kilns, ball mills and roller mills, vibration and temperature sensors provide early warnings for bearing wear, gearbox issues, shaft imbalance, and hot spots. Motor current and power monitoring complement this by detecting electrical or load anomalies that vibration alone might miss.

Common sensor types include:

- Vibration sensors for bearings, gearboxes and imbalance

- Temperature probes or thermal sensing for hot spots and refractory wear

- Motor current and power monitoring for load abnormalities

When selecting sensors, evaluate key specifications such as sampling rate, frequency range, g-range, temperature tolerance, ingress protection, and battery life. These factors ensure early bearing frequencies and low-frequency gearbox sidebands are captured accurately.

Ease of installation matters too. Look for compact devices that reduce mounting complexity and minimize cabling in high-dust environments.

Consider Multi-parameter sensors, such as the MachineDoctor, that simplify mounting, reduce cabling in dusty environments, and provide early fault detection. Such sensors have successfully prevented failures in cement plant equipment, including $500,000 planetary gearboxes.

Finally, ensure the solution integrates seamlessly with your CMMS. Alerts should generate prioritized work orders with diagnostic evidence attached so maintenance teams can plan accordingly.

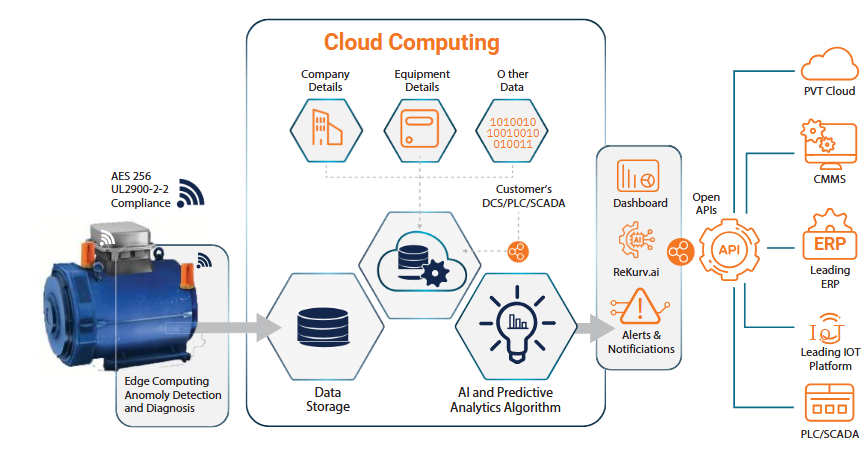

Confirm enclosure ratings, mounting options, and gateway compatibility (cellular, Wi-Fi, or wired). Edge processing capabilities can reduce bandwidth requirements while preserving actionable insights, improving both deployment speed and scalability.

3. Analytics: AI Anomaly Detection & Guidance

Analytics must demonstrate early detection and explainability. Ask vendors to quantify:

- Detection lead time (days or weeks before failure)

- Precision and recall

- False positive rate

AI-driven anomaly detection should clearly identify why an asset is flagged, referencing spectral signatures, temperature deviations or load anomalies. Trend visualization should connect anomalies to specific components. Nanoprecise’s Condition Intelligence does this well.

Prescriptive guidance should specify:

- Which component to inspect

- Which spare to stage

- Urgency level

This reduces diagnosis time and shortens MTTR. Prefer platforms that combine edge analytics with cloud-based model improvement so supervised feedback strengthens detection accuracy over time.

4. Integrations and Security

Predictive insights must flow cleanly into your operational systems. Confirm compatibility with common industrial protocols such as OPC UA, Modbus RTU/TCP, MQTT and REST APIs.

Review architecture diagrams showing PLCs, edge gateways and data flow into analytics platforms. Ensure your OT team can validate latency, firewall rules and segmentation.

CMMS integration is critical. Alerts should automatically create prioritized work orders with diagnostic attachments, technician assignments and parts staging instructions.

Confirm encryption in transit and at rest, role-based access controls and documented data ownership policies. Enterprise-grade security compliance and clear incident response processes should be established before full deployment.

5. ROI & Total Cost of Ownership

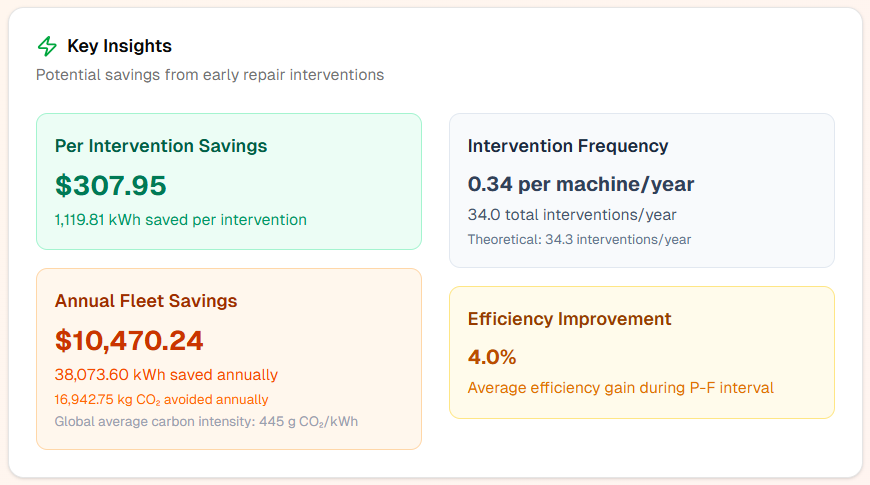

Build a business case using realistic benchmarks. Many cement operations see meaningful reductions in unplanned downtime and maintenance costs when anomaly detection and prescriptive guidance are implemented effectively. Model savings using a simple formula:

Annual Savings=

(Baseline downtime hours × cost per hour × expected reduction) + parts and labor savings.

Alternatively, a repair savings calculator can quantify the financial impact of early interventions versus running equipment to failure, making downtime avoidance tangible for leadership.

Review total cost of ownership, including:

- Sensor hardware and mounting

- Gateways and connectivity

- Analytics licensing

- Integration engineering

- Ongoing support

Prioritize solutions that offer straightforward deployment, minimal installation disruption, and scalable subscription models to accelerate time to value. Track avoided downtime hours, reduced parts usage, and MTTR improvements to create a repeatable ROI template across equipment lines and sites, ensuring your predictive maintenance investments deliver measurable, ongoing impact.

6. Vendor Evaluation Checklist

Use a weighted scorecard to evaluate vendors objectively:

- Sensor coverage and hardware durability (20%)

- Analytics accuracy, explainability and prescriptive guidance (25%)

- CMMS an/or SCADA integration (20%)

- Security and compliance (15%)

- Ease of implementation and deployment support (20%)

Require comparable metrics and documented success criteria across all vendors. Prioritize solutions that demonstrate clear understanding of kiln, ball mill and roller mill behaviour and provide AI-driven workflows that maintenance teams can execute confidently.

Choose the Right Predictive Maintenance Software for Your Cement Plant

Select software that aligns with your most critical assets, clearly defines measurable KPIs and provides explainable AI anomaly detection with prescriptive actions.

Start by listing your top three assets with the highest downtime cost — whether rotary kilns, ball mills, roller mills, gearboxes or conveyors — and evaluate solutions based on sensor compatibility, integration readiness and repair savings potential.

When predictive insights map directly into prioritized work orders and measurable repair savings, predictive maintenance becomes a scalable operational advantage rather than a disconnected monitoring system!

How Nanoprecise Helps Cement Plants

When predictive insights are actionable, measurable, and integrated, predictive maintenance transforms from a monitoring tool into a scalable operational advantage.

Nanoprecise helps cement plants achieve this by combining multi-parameter sensors, explainable AI anomaly detection, and prescriptive guidance with seamless CMMS integration. Its Edge-to-Cloud architecture reduces installation complexity, preserves bandwidth, and ensures alerts automatically generate prioritized work orders with diagnostic evidence attached.

FAQ

PdM detects issues early on cement equipment, including bearing, gearbox and refractory issues. reducing unplanned downtime and emergency repairs. AI-driven alerts with prescriptive actions improve MTTR, optimize parts planning and stabilize production across kilns, ball mills, roller mills and conveying systems.

The best predictive maintenance platforms for cement plants combine continuous condition monitoring with multi-parameter sensors, AI-Driven intelligence for guidance and seamless CMMS integration. Effective solutions monitor vibration, temperature, and power to detect early-stage failures in critical assets while automating work order creation in your CMMS.

Nanoprecise is a leading option for cement producers seeking predictive maintenance. Our 6-in-1 wireless sensor enables more accurate fault detection in harsh plant environments. Nanoprecise has also been recognized by Deloitte’s Fast 500 and The Globe and Mail.

Get your brochure on PdM Solutions for Cement Plants

Cement plants typically use vibration sensors, temperature probes and motor current monitoring for kilns, ball mills, roller mills, crushers and conveyors. Multi-parameter sensors, like MachineDoctor, are generally a preferred option as the devices simplify installation in dusty, high-heat environments while enabling early anomaly detection.

While there are many companies offering vibration analysis for kilns. Advanced platforms like Nanoprecise combine continuous vibration monitoring (and more) for allthe rotating machinery in your cement plant with AI-based condition monitoring and condition intelligence to guide cement operations.

AI models analyze vibration, temperature and power data to detect subtle deviations before failure. It then provides explainable insights and recommends actions that integrate into CMMS workflows.