Preventing a $20K Repair and $200K Equipment Failure on Dewatering Centrifuge at Water Treatment Plant

Executive Summary

A large municipal water treatment plant in the US implemented predictive maintenance to improve the reliability of its industrial water recycling operations, specifically around their dewatering centrifuge. Operating in a drought-prone region and managing one of the country’s most advanced water reuse systems, the facility depends on continuous operationto process billions of gallons of water annually.

Using continuous vibration monitoring, the maintenance team detected a late-stage unbalance fault on a dewatering centrifuge caused by material buildup. Early detection enabled timely cleaning, avoiding a $20,000 manual repair and preventing a potential catastrophic equipment failure valued at up to $200,000.

The Result: Extended equipment lifespan, avoided downtime, and a shift toward condition-based maintenance.

Water Treatment Plant Customer Profile

The facility is a major U.S. water and wastewater utility serving residential, commercial, and industrial users. It operates more than 500 miles of piping and processes approximately 9 billion gallons of water annually, much of which is recycled for irrigation, cooling towers, and industrial applications.

As part of a multi-stage treatment process, the facility relies on large dewatering centrifuges to remove solids during water recycling. These centrifuges operate under demanding conditions and are highly sensitive to material buildup, making reliability and early fault detection critical.

The Challenge of Dewatering Centrifuges

Dewatering centrifuges play a critical role in the filtration process, operating continuously under variable loads and exposure to solid material accumulation. While routine maintenance is scheduled every 4,000 operating hours, material buildup can occur unexpectedly between service intervals.

This buildup creates unbalance between the centrifuge bowl and scroll, increasing vibration and placing excessive stress on mechanical components. If the buildup exceeds Clean-In-Place (CIP) limits, the centrifuge must be manually opened and cleaned, which is a labor-intensive process requiring 2–3 days and approximately $20,000 in repair costs.

If left unaddressed, prolonged unbalance could lead to severe mechanical damage and partial equipment replacement, with costs reaching $200,000.

Solution Deployed

To improve reliability and reduce risk, the water treatment facility deployed the Nanoprecises’ Energy-Centric Predictive Maintenance solution across its critical assets, with a specific focus on centrifuge vibration behaviour.

The solution included:

- Wireless sensors with 6-in-1 machine condition monitoring, including vibration monitoring.

- Automated fault detection for timely maintenance action

- Late-stage fault notifications for critical thresholds.

- Cloud-based dashboards for maintenance visability.

The system continuously analyzed vibration patterns to detect unbalance caused by material buildup, enabling early intervention before mechanical damage occurred.

Assets Monitored

- Dewatering Centrifuges

- Vertical Pumps

- Flare Blowers

- Odor Control Fans

- Induced Draft (ID) Fans

MachineDoctor sensors mounted.

Observation & Analysis

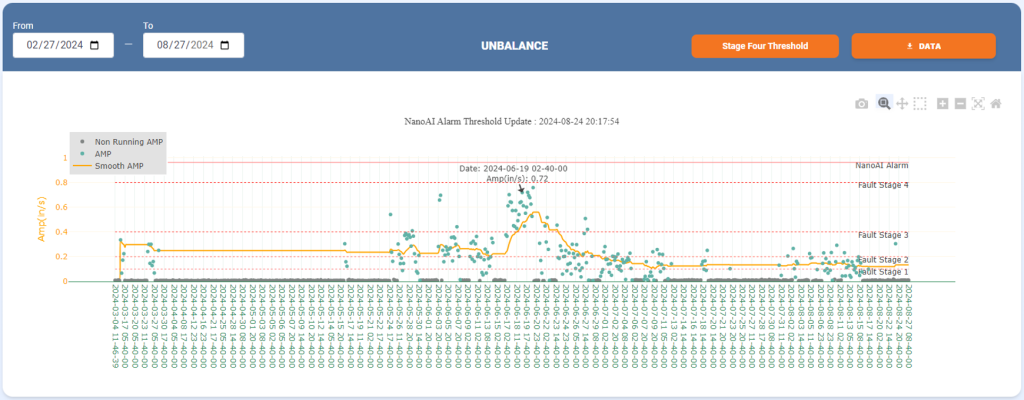

Unbalance Detection on Dewatering Centrifuge

- A significant increase in the 1X vibration amplitude was detected, indicating unbalance due to material accumulation.

- The system generated a late-stage fault alert, notifying the operations team that vibration levels had exceeded acceptable limits.

- The alert provided sufficient lead time to intervene before the issue escalated into mechanical failure.

Without intervention, continued operation under unbalanced conditions could have caused accelerated wear, reduced efficiency, and damage to critical internal components.

Corrective Action

- The cleaning successfully resolved the unbalance.

- Post-maintenance vibration levels returned to normal operating ranges.

- No manual disassembly or extended downtime was required.

effectiveness of the maintenance intervention.

Outcomes & Impact

Avoided Repair and Replacement Costs:

- $20,000 manual cleaning and labor costs avoided

- $200,000 in potential equipment replacement costs prevented

Improved Equipment Reliability

- Early detection prevented secondary damage to internal components

- Centrifuge operational efficiency was preserved

Extended Asset Lifespan

- Proactive intervention reduced long-term mechanical stress

- Remaining useful life of the centrifuge was extended

Reduced Downtime Risk

- Maintained uninterrupted water recycling operations

- Avoided 2-3 days of unplanned maintenance

Conclusion

By implementing predictive maintenance and continuous vibration monitoring, this U.S. water utility transitioned from time-based servicing to condition-based maintenance for its most critical equipment.

Early detection of unbalance caused by material buildup enabled timely corrective action, preventing costly repairs, extending equipment life, and avoiding a potential six-figure failure.