Using AI Predictive Maintenance in Semiconductor Manufacturing

Executive Summary

A North American semiconductor manufacturer relies on hundreds of mechanical dry pumps to maintain stable vacuum conditions across critical subfab processes. Any pump degradation can disrupt vacuum stability, increase contamination risk, and trigger costly unplanned downtime, directly impacting wafer yield and throughput.

To reduce operational risk, the manufacturer deployed Nanoprecise’s predictive maintenance solution across its pump fleet to gain continuous visibility into asset health and enable proactive maintenance. After deployment, the MachineDoctor™ IoT sensors detected early-stage mechanical degradation in a two-stage vacuum pump.

Result: This early detection allowed the maintenance team to schedule a controlled pump replacement, preventing process disruptions, potential wafer scrap, and unplanned downtime

Semiconductor Manufacturer Customer Profile

The customer is a leading North American semiconductor manufacturer with hundreds of pumps supporting critical subfab processes. In these environments, vacuum stability, precise pressure control, and safe handling of process byproducts are essential for:

- Maintaining wafer yield

- Ensuring process stability across chemical/vapor deposition, etch, and lithography

- Supporting continuous line throughput

With operational risk high, even minor pump degradations can cascade into scrapped wafers, emergency maintenance, or production downtime. Proactive condition monitoring of semiconductor manufacturing equipment was a strategic priority.

The Challenge

Pumps in semiconductor subfabs operate under continuous, demanding conditions, experiencing:

- Thermal stress

- Chemical byproducts exposure

- Sustained mechanical loading

Internal degradation escalates quickly once faults begin. Even minor wear can increase contamination risk, introduce process drift, or force emergency maintenance interventions. Traditional periodic inspections and time-based maintenance were insufficient to mitigate these risks across a large pump fleet.

Solution Deployed

The semiconductor manufacturer deployed Nanoprecise’s IIoT Sensors on:

- Dry Pumps

- Vacuum Pumps

- Blowers

- Booser Fans

Data was transmitted from the edge to the cloud, where AI-driven analytics provided actionable insights through the Nanoprecise dashboard. Automated alerts enabled maintenance teams to act on early-stage anomalies before they escalated.

Semiconductor Manufacturing Equipment Monitored

Some, but not all, of the monitored assets included:

- Two-stage vacuum pumps

- Dry pumps critical for wafer processes

- Process blower and booster fan assemblies

- Auxiliary vacuum support equipment

Observation & Analysis

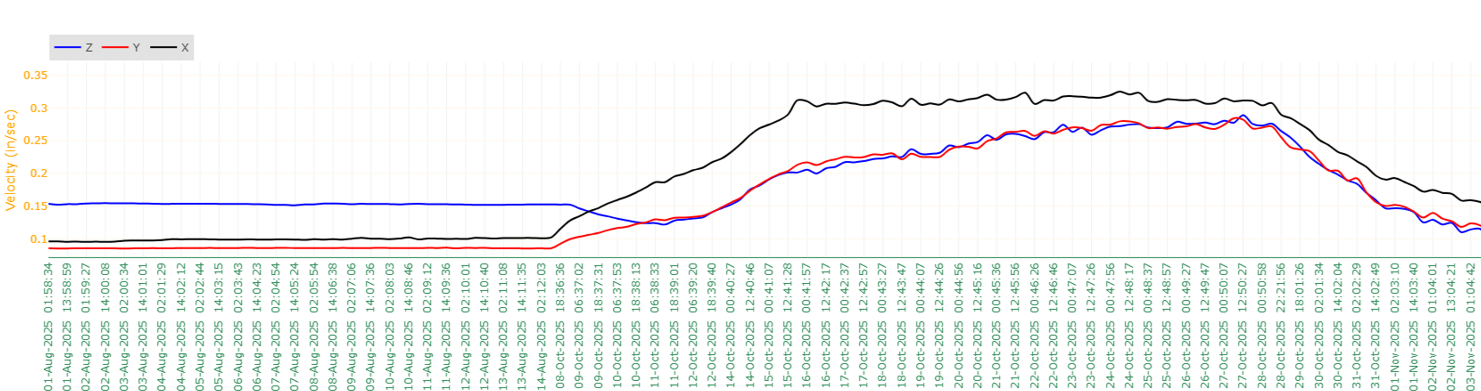

Emerging Vibration Trend

- Nanoprecise sensors detected a rapid increase in RMS velocity on the lower stage of the vacuum pump.

- The upward trend was clearly visible in the vibration monitoring data, indicating accelerating mechanical degradation (Figure 1).

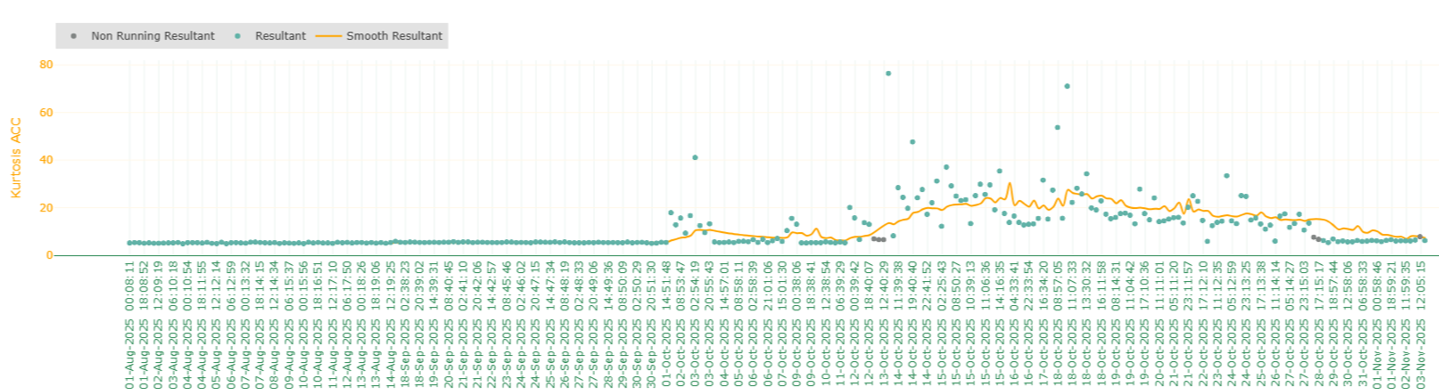

Impulse and Impact Behavior

- Kurtosis trends showed a sharp rise, signalling an increase in impulsive events within the pump (Figure 2).

- Time waveform comparisons before and during the event revealed pronounced impacts consistent with mechanical contact.

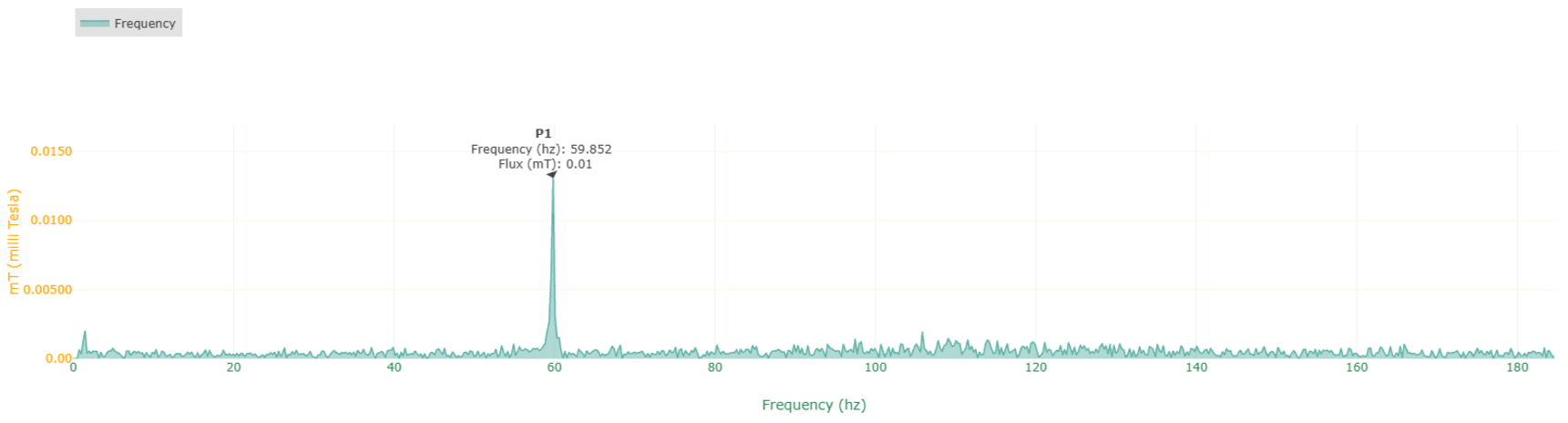

Correlation & Diagnostic Confidence

- Frequency analysis indicated a rapid increase in the 1X shaft speed (~3500 RPM) of the motor and pump.

- The running speed was independently verified using electromagnetic flux spectrum data from the lower pump motor (Figure 3).

Outcomes & Impact

Nanoprecise automatically alerted maintenance teams to the abnormalities.

An inspection by the maintenance team found that the pump was emitting unexpected noises, and metal shavings were visible in the pump exhaust, suggesting that pump lobes or vanes were in contact.

This information empowered the semiconductor manufacturer to:

- Shift from reactive to proactive =with an early-stage alert that allowed them to plan maintenance accordingly.

- Replace a two-stage vacuum pump without production downtime

- Prevent potential wafer scrap, line disruption, and emergency maintenance costs

- Gain continuous visibility into pump fleet health, supporting data-driven decision-making

Key Outcomes For the Customer

- Early warning and anomaly detection across the pump fleet

- Improved maintenance planning and resource allocation

- Enhanced semiconductor manufacturing process stability

- Reduced operational risk in semiconductor subfab equipment

- Higher uptime, throughput, and lower cost of ownership

Conclusion

In semiconductor manufacturing, even a single pump failure can ripple across critical subfab processes, affecting wafer yield, throughput, and process stability. By leveraging vibration analysis, impulse and impact monitoring, shaft frequency analysis, and AI-driven analytics, Nanoprecise empowered this manufacturer to detect early-stage faults, plan maintenance proactively, and avoid production disruptions.