Energy-Centered Predictive Maintenance Food & Beverage: How a $1B Dairy Product Producer Avoided Downtime

Executive Summary

Nanoprecise partnered with a leading North American dairy producer with over $1B in annual revenue to protect the reliability of its proprietary ultra-filtration milk production process. With production assets distributed across large facilities, including many in remote or hard-to-reach locations, the company required a solution that could autonomously monitor equipment health and detect failures early without disrupting operations.

Using Nanoprecise’s Energy-Centered Predictive Maintenance platform, the facility continuously monitored critical motors, fans, pumps, compressors, and blowers. The system detected an emerging unbalance fault on a 30 HP motor driving a reverse osmosis (RO) pump—a critical component in the ultra-filtration process.

The result: Reduced downtime risk, lower maintenance costs, improved equipment reliability, and uninterrupted production of high-quality dairy products.

Dairy Customer Profile

A North American leader in producing milk and milk-based products with a patented ultra-filtration process that concentrates natural milk protein while removing lactose and sugars.

This specialized manufacturing process relies on the continuous operation of motors, pumps, and filtration systems. Any disruption, particularly in reverse osmosis systems, can directly impact throughput, product consistency, and delivery commitments. As a result, asset reliability is mission-critical.

The Challenge

The facility operates numerous rotating assets across large production areas; many located in remote or difficult-to-access locations. Traditional inspection-based maintenance made it difficult to detect early-stage mechanical issues, particularly those developing gradually under variable operating speeds.

The reverse osmosis pump motor plays a central role in the ultra-filtration process. Without continuous monitoring, early unbalance or looseness issues could escalate into:

- Severe vibration exceeding safe operating limits

- Accelerated wear on motor mounts and structural components

- Emergency shutdowns impacting milk processing throughput

- Increased safety risks and higher reactive maintenance costs

The facility needed a quick-to-deploy, autonomous condition monitoring solution capable of identifying subtle fault progression before failure occurred.

Solution Deployed

Nanoprecise implemented its Energy-Centric Predictive Maintenance solution, providing continuous, AI-driven insights into asset health.

Key Capabilities included:

- Wireless sensors with 6-in-1 machine condition monitoring, including

- Triaxial vibration

- Acoustic emissions

- Magnetic flux

- Temperature

- Automated fault detection and alerting

- Advanced FFT, waterfall, and trend analytics

- Cloud-based dashboard for real-time visibility

- Validation of corrective actions post-maintenance

Within months, the system detected abnormal vibration behavior on a 30 HP RO pump motor, triggering early intervention.

Assets Monitored

- AC Motors

- Reducer Gearboxes

- Centrifugal Pumps

- Compressors

- Centrifugal Blowers

- Agitators

- Boiler Fans

- Homogenizers

- Separatprs

- Reverse Osmosis pumps

- Processing Pumps

Observation & Remediation Process

Reverse Osmosis (RO) Pump Motor

In early July 2024, a Nanoprecise sensor detected an emerging fault on a 30HP motor powering a reverse osmosis pump at one of it’s largest US plants, and notified the team.

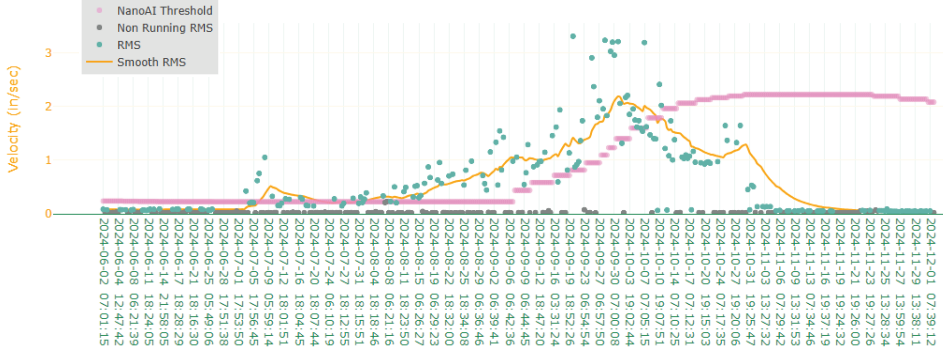

Amplitudes exceeded automated thresholds and continued to increase until corrective action was taken. Vibration returned to acceptable levels post-repair.

exceeded automated thresholds in July 2024 and continued to increase until corrective

action was taken. Vibration returned to acceptable levels post-repair.

Spectral Analysis & Fault Identification

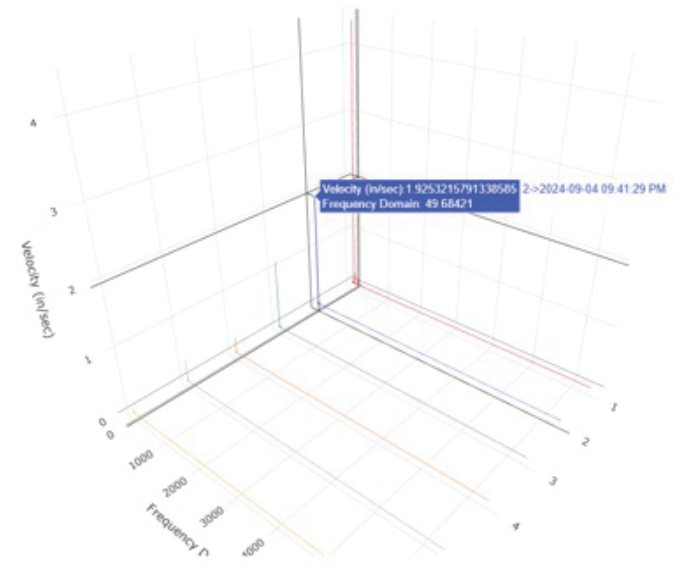

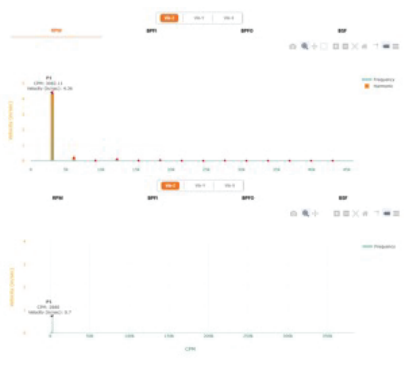

Spectral analysis through inspection of waterfall plot (Fig 2.), individual FFT timestamps (Fig. 3), and automated tracking of 1X amplitudes through Nanoprecise Dashboard (Fig 4.), identified an emerging 1X fundamental frequency of motor shaft speed, driving amplitude increases.

Figure 2: Waterfall Plot of Velocity Spectra (July 2024 to October 2024). This plot shows the emerging 1X fault frequency at approximately 48-50 Hz.

Figure 3: FFT Spectra Timestamps. Severity is evident when fault is near maximum mplitude (top) versus amplitude post corrective action (bottom).

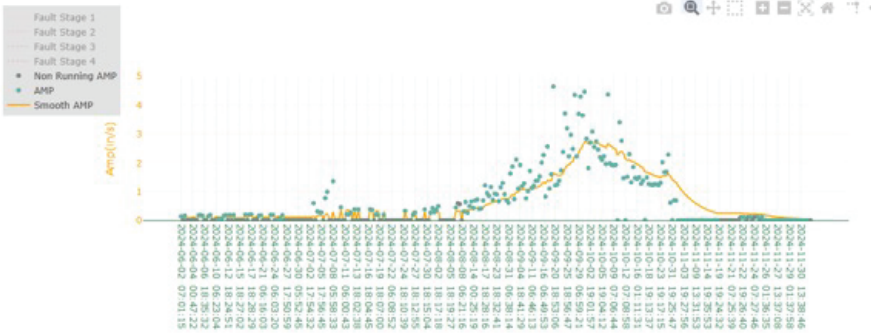

tracks the isolated amplitudes of the 1X band (identi ed from motor ux FFT) and

illustrates the severity of this fault and its validated correction.

Corrective Action & Validation:

Based on Nanoprecise recommendations, plant personnel conducted a targeted inspection during the next maintenance window.

Findings Included:

- Damaged motor mounts and frame

- Structural looseness contributing to excessive vibration

- Operating speeds intersecting resonance zones

Corrective Actions Taken

- Repair of motor mounts and frame

- Adjustment of VFD speed ranges to avoid resonance bands (2400–3000 RPM)

Post-maintenance data showed an immediate and sustained reduction in vibration across all measured parameters, confirming fault resolution.

Outcomes & Impact

- Avoided Unplanned Downtime: Early detection allowed maintenance to be planned rather than reactive, preventing a potential failure of a critical RO pump motor.

- Reduced Maintenance Costs: Relatively inexpensive structural repairs replaced what could have escalated into a major motor or pump replacement.

- Extended Equipment Life: Correcting unbalance and resonance reduced mechanical stress, extending the remaining useful life of the motor and associated components.

- Improved Safety: Planned intervention eliminated the risks associated with emergency repairs in high-energy rotating equipment.

- Increased Operational Visibility: Continuous condition monitoring gave the maintenance team confidence in asset health and validated the effectiveness of corrective actions.

Conclusion

Nanoprecise’s Energy-Centered Predictive Maintenance solution enabled this leading dairy producer to protect a critical reverse osmosis system at the heart of its ultra-filtration process.

By detecting early-stage unbalance and structural issues, Nanoprecise helped the facility avoid costly downtime, optimize maintenance decisions, and maintain consistent production of high-quality dairy products.

In food and beverage manufacturing—where equipment reliability directly impacts product quality, safety, and profitability—predictive maintenance is no longer optional. With Nanoprecise, maintenance teams gain the insight needed to act early, fix precisely, and operate with confidence.