“Health Status shouldn’t just be a label on your dashboard; it should turn complex machine behavior into insightful actions. When teams can see what’s changing and why, they don’t just react, they act with confidence.”

Kareem Younis, Sr. Product Manager, Nanoprecise.

When “Healthy” Isn’t Helpful Anymore

You’re reviewing last night’s alert log. A critical rotating asset showed elevated vibration velocity in the horizontal axis, just above its baseline, but below fault thresholds. The overall status? “Acceptable.” No alarms. No work orders. Nothing is actionable.

Until it fails.

This isn’t a technological failure. It’s an interpretation failure.

In today’s asset-intensive environments, teams don’t lack data; they lack clarity. They have graphs, alerts, baselines, and alarms. But too often, they don’t have a coherent answer to the question: “Is this machine actually healthy?”

At Nanoprecise, we believe Health Status should answer that question. And not with a static label, but with a real-time, context-rich understanding of asset conditions.

The Hidden Risk of “Status Quo” Health Scoring

Many health indicators today are built on thresholds. They react when something crosses a limit. But failure rarely announces itself so clearly. Instead, it builds gradually, across parameters, over time, and often under the radar. This creates a blind spot:

- Machines degrade without triggering a fault

- Alerts become noise without a signal of severity

- Maintenance teams act late or not at all, unsure of what’s truly urgent

In short: we’re watching machines. But we’re not understanding them.

Why Health Status Matters Now

As operational complexity grows and teams manage more assets with fewer hands, it’s no longer enough to know if something has changed. You need to know:

- What changed

- How bad it is

- Where it’s headed next

Nanoprecise’s Health Status does exactly that. It brings together real-time sensor signals, fault algorithms, alert patterns, and contextual intelligence, so you can go from “I think it’s fine” to “I know what to do next.”

It’s not just a label. It’s a system.

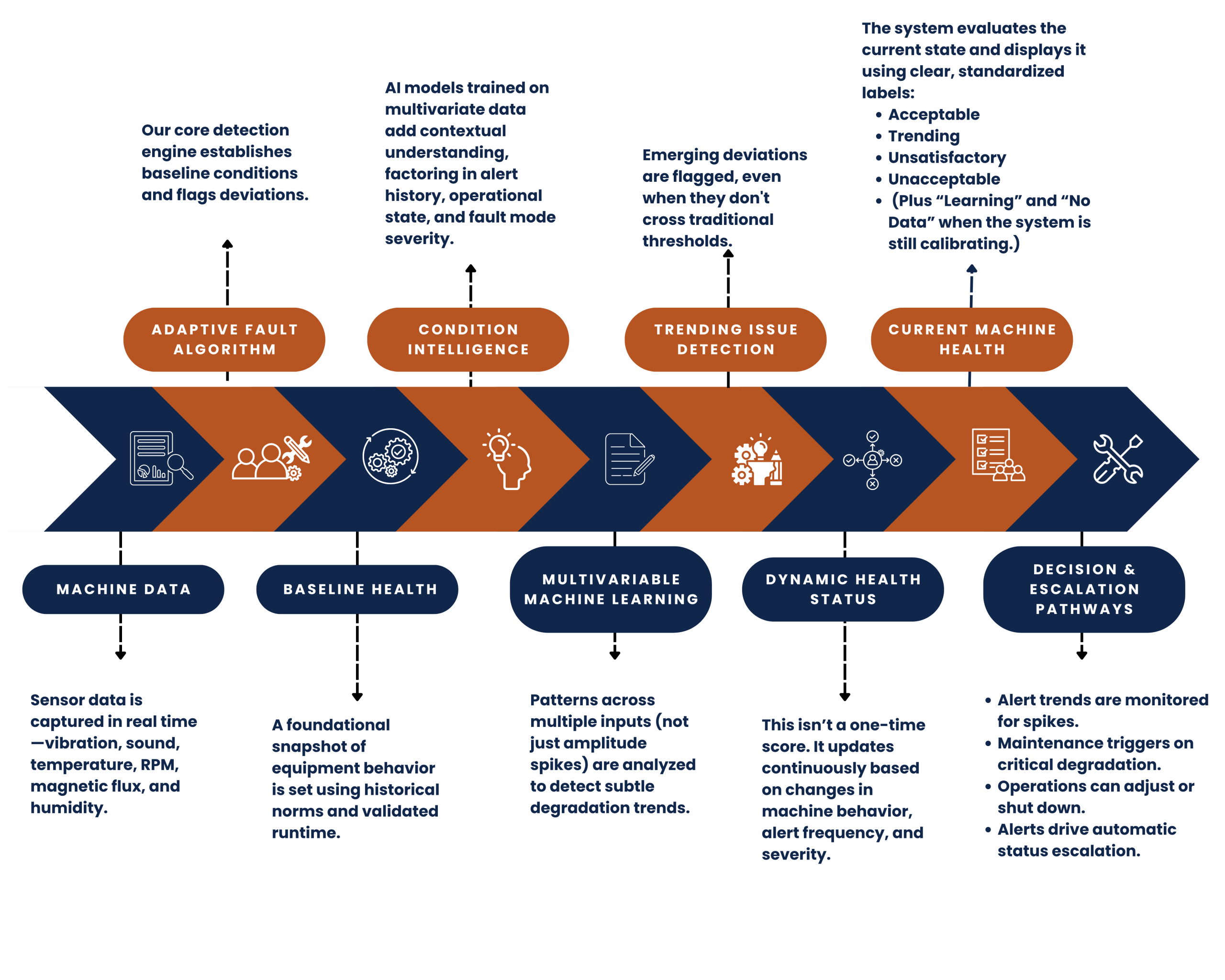

A Look Inside the System: What Powers Health Status

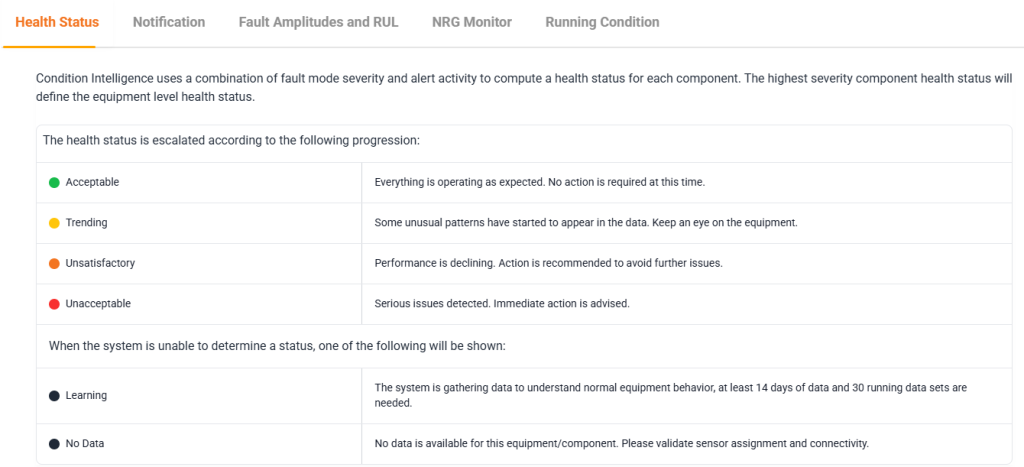

To understand how it works, let’s walk through the flow that drives every Health Status output. This diagram isn’t theoretical. It reflects exactly how Health Status is computed and escalated inside the Nanoprecise ecosystem:

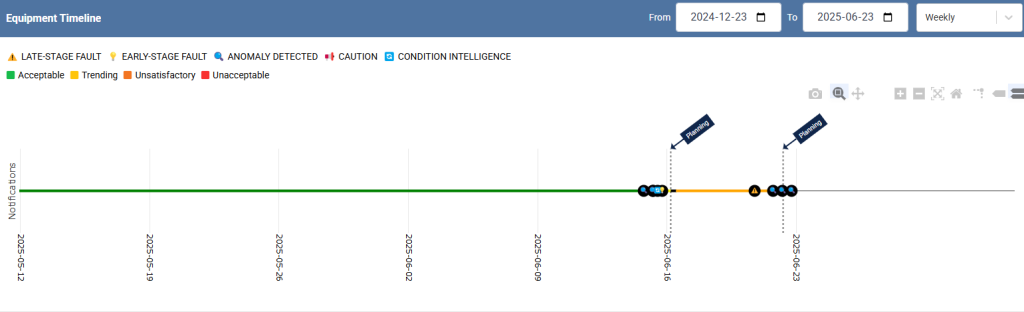

Seeing the Story: The Health Status Timeline

Machines fail gradually. A subtle vibration change here, a temperature uptick there, a minor alert that doesn’t seem urgent, until it is.

That’s why we built the Health Status Timeline: to make degradation visible, before it becomes disruptive.

This compact, color-coded visual gives teams a chronological view of how health status has evolved, across days, weeks, or even months. Instead of relying on one-off alerts or spot checks, you can now trace a clear history of:

- When a machine first started trending away from its baseline

- How quickly a status escalated from Acceptable to Unsatisfactory

- Whether past maintenance stabilized the condition, or only paused it

- Correlation between health changes and operational or environmental shifts

- It’s not just a historical log. It’s a diagnostic tool.

The timeline helps teams answer:

- “Did this issue start after the last shutdown?”

- “Was there a slow decline, or a sudden drop?”

- “Is this the same trend we saw six months ago, or something new?”

What This Means for Your Team

With this approach, Health Status becomes far more than a tag on a dashboard. It becomes a decision-making layer across your reliability program:

Maintenance planners know which equipment to prioritize

Technicians get clearer signals, not guesswork

Operations can adjust loads or run schedules based on real-time condition

Leadership gains confidence that risks are visible and controllable

This replaces reaction with readiness.

Why It’s Critical to the Future of Maintenance

Health Status aligns with how modern maintenance should work:

- Powered by data

- Interpreted with intelligence

- Prioritized for action

And it complements other Nanoprecise layers, like our Multiview Dashboard, Condition Intelligence, and Energy Monitoring, to give every team a full-spectrum view of asset behavior.

This isn’t about showing more data. It’s about giving that data meaning.

Final Thoughts

In industrial reliability, confidence comes from clarity.

Health Status is part of how we deliver that clarity, by interpreting complexity, identifying patterns, and prompting action early.

Because when your equipment speaks clearly, your team can act with confidence. Interested in learning more? Talk to our team, today or take a quick tour of our dashboard online.

About the Author

Kareem Younis is Senior Product Development Manager at Nanoprecise, building cutting-edge solutions that turn asset-level insights into enterprise-wide impact.

With experience spanning engineering, automation, and strategy, from Deloitte Consulting to leading product and partnerships across North America, Kareem brings a practical, cross-functional lens to digital transformation in maintenance.

He holds an MBA in AI from Kellogg and a B.S. in Industrial & Systems Engineering from the University of Minnesota. His work centers on making maintenance data matters, operations, finance, and sustainability.