ARTICLE

As the Industrial Internet of Things continues to expand and evolve, so does our need for power. The increasing need for sustainable power sources has paved the way for Energy Harvesting devices.

The Industrial Internet of Things- or IIOT- refers to the network of smart sensors and applications that facilitate machine-to-machine communications, by connecting equipment components to each other and to applications. These devices can capture & transfer data, and provide information about the health & performance of machines. They function with the help of a power supply, that generally originates from batteries or electric points.

As the Industrial Internet of Things (IIoT) continues to evolve, so does our need for power. In many cases, the Industrial IoT devices are powered using a battery, enabling a truly wireless application. The requirement to change batteries can be a negative feature in some cases and there is an increasing interest in self-powered devices with the capacity to generate & store power using renewable sources. The desire for self-sustaining power sources in IoT has paved the way for Energy Harvesting devices.

How does it work?

Energy harvesting is the collection of energy from ambient operating environmental energy sources, which is then used to power wireless IoT devices. It is the process of converting some form of ambient energy into power for a device.

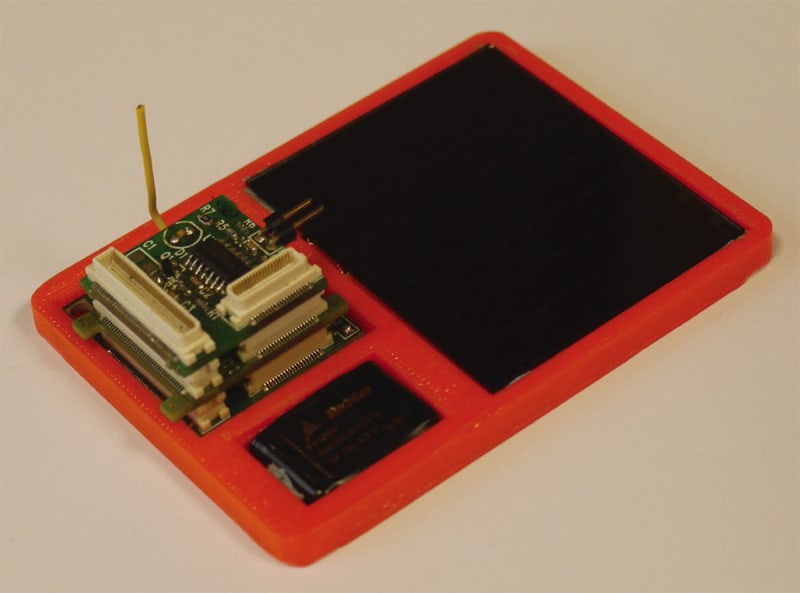

Sensor node architecture with harvested energy being used directly by the Sensor

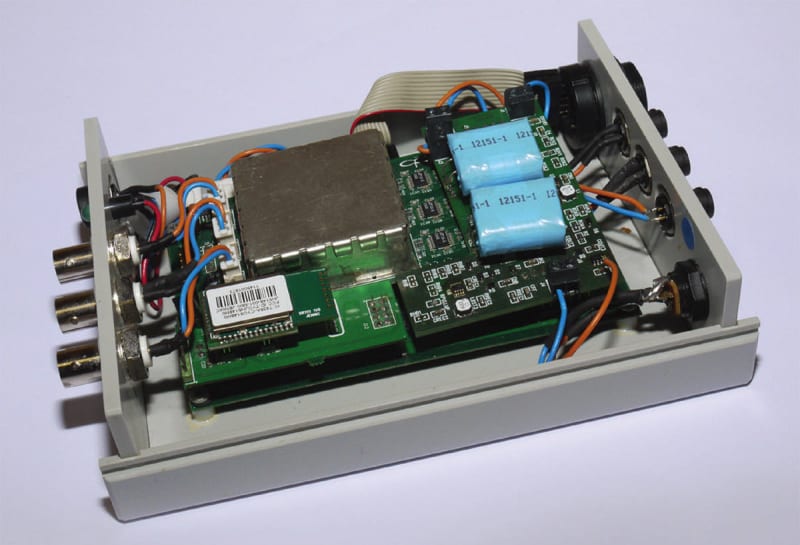

The general architecture of an energy harvesting industrial IoT Sensor consists of harvesters that convert available energy to electrical energy. The energy captured may be used directly by the sensor or can be stored for later use. Generally, rechargeable batteries or supercapacitors are used for storing energy.

Sensor node architecture with harvested energy being stored for future use by the sensor

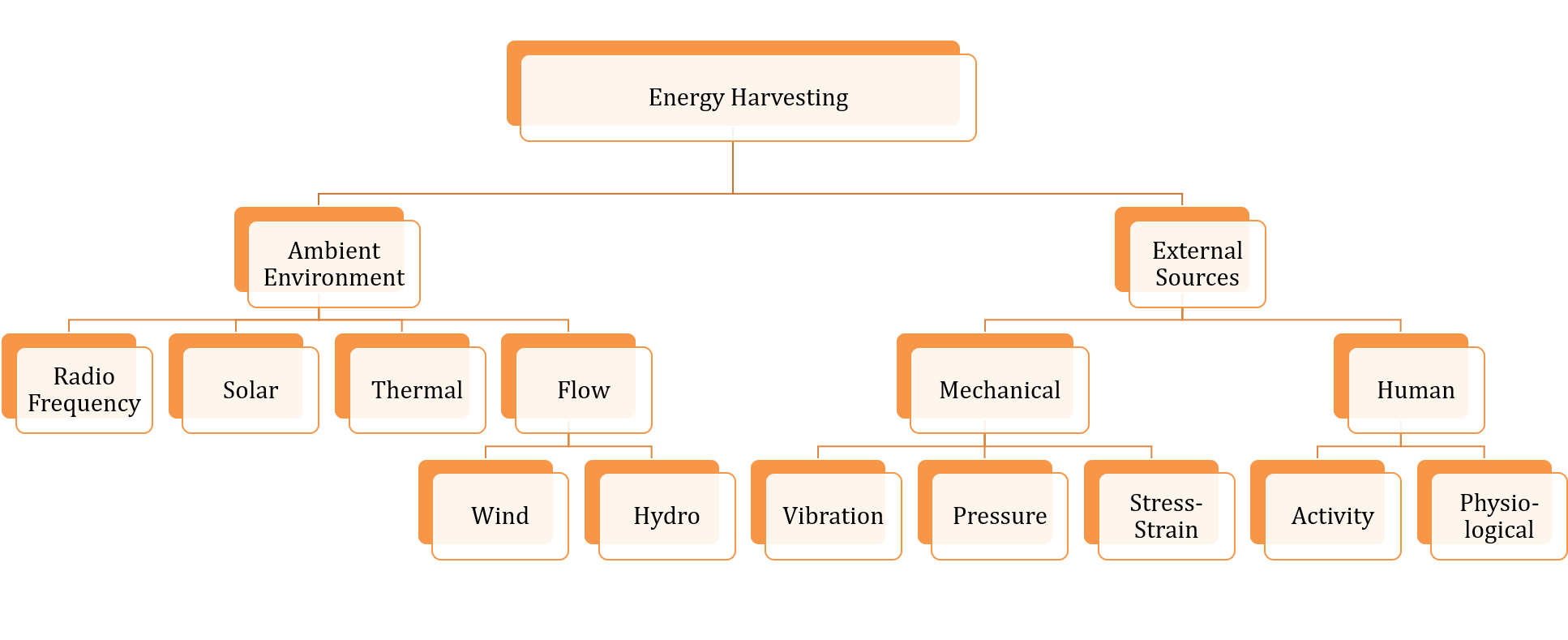

Different types of Energy Harvesting

Energy Harvesting IoT devices have the potential to harvest different forms of ambient energy as well as energy from external sources. Ambient Energy sources include Solar, Thermal, Flow, and Radio Frequency, while external sources can be categorized as Mechanical and Human sources. The below chart details the different types of energy that can be harvested by devices for powering themselves.

The goal of using Energy Harvesting wireless IoT sensors is to give these sensors a nearly unlimited source of on-the-go power without having to wire it to the main power.

Advantages of Energy Harvesting Devices

Energy harvesting in industrial IoT can offer various advantages over wired or battery-powered IoT devices. Some of the advantages are listed below:

- Industrial IoT hardware with Energy Harvesting eliminates the need for running wires to devices. This ensures a hassle-free deployment with a simple Plug & Play feature.

- They eliminate the constraint of replacing batteries.

- Industrial IoT devices require ultra-low power, which makes Energy harvesting devices compact in nature.

- They are a promising solution to power Industrial IoT, especially in remote, hard-to-reach, or unsafe areas where maintenance of devices is not desirable or perhaps even feasible.

- It facilitates businesses or organizations to drive digital transformation, which was previously unaffordable due to the high energy, installation, and upkeep costs of IoT devices.

IoT devices with Energy Harvesting can provide myriad benefits to the consumers as well environment due to their ability to replace existing energy sources while maintaining the full functionalities of the devices.

Why Use Energy Harvesting – Benefits

Adopting a suitable energy harvesting technology to power industrial IoT Sensors may be the next step in the shifting landscape of Industrial IoT. With the rising need for continuous, real-time monitoring of equipment, the desire for economic self-powering hardware that can sustain adequate data capture & upload rates is very high. These devices offer significant benefits:

- Energy Harvesting enables the industrial IoT devices to function without the need for an external power supply, thereby enabling them to be used in hazardous and explosive environments.

- Industrial IoT has discovered applications in a wide variety of applications in numerous sectors. However, one of the major concerns is providing continuous energy supply to devices that are located in remote locations. Energy Harvesting helps to mitigate this challenge by providing a self-charging capability to devices and avoids the costs of wiring or the need to replace batteries. An interesting example to consider is in pipelines where running wiring hundreds of kilometers to power sensors is not attractive.

- Temperature is known to have a significant impact on the performance and lifetime of traditional batteries. Extremely low & high temperatures lead to performance degradation and can cause irreversible damage to Lithium-ion batteries. Applications at high temperatures cause faster aging of the batteries. These cases may require batteries to be replaced/charged more frequently. Energy harvester technology charges from the ambient operating environment and therefore does not require any special attention towards charging, once selected and specified properly.

- In some cases Energy Harvesting technology does not possess any moving parts and constitutes a simple design, making them resistant to wear & tear.

- Typical battery manufacturing processes lead to environmental impacts that are becoming more common for consideration in business planning and economic analysis. The increased demand stemming from the need for replacement aggravates this issue. Energy harvesting IoT devices can help to mitigate this problem with their self-charging capability.

Disadvantages of Energy Harvesting Devices

While energy harvesting devices offer a number of advantages when it comes to Industrial IoT, it is not without downsides. Some of them are listed below:

- Energy Harvesting IoT devices can lead to significant cost increases for the hardware when compared to battery-powered hardware of a similar type. In many cases it can 2X or more the cost of the hardware, making it the primary challenge for large-scale adoption. With higher initial costs, the demand for better RoI would need to go up as well, which may result in organizations shying away from its adoption.

- With the technology at a nascent stage, the power generated from energy harvesting is often low. Inadequate energy production may cause the device to power down unexpectedly, ceasing its complete functionality. Therefore, it is essential to strike a balance between power generation with consumption with a suitable safety factor based on the criticality of operation/ application.

- One of the other disadvantages would be the availability of ambient energy. The generation of power by energy harvesting IoT devices depends on the ambient energy available. This is also affected by the position/placement of the device in relation to the energy source and may lead to sub-optimal performance of the main IoT purpose.

- In addition, the lifespan of these devices may be limited due to various factors such as higher charge-discharge cycles. The full life of these devices is unknown due to the early stage of their deployments. If the average life span of the energy harvesting device is not sufficiently longer than that of a simple battery cell then the increased cost may not be justified. Further, if the life of the main IoT device an energy harvesting cell is attached to is short then the longevity of the energy harvesting device may be irrelevant.

Factors affecting the adoption of Energy Harvesting IoT devices

The adoption of energy harvesting has the potential to propel Industrial IoT adoption. However, the adoption would depend on a number of factors such as:

Amount of energy required

The objective of the Device is to generate enough energy to power the data collection and transmission effectively. Energy harvesting may not a feasible alternative for devices that collect & transmit a higher amount of data as it may require higher energy, thereby draining the power faster than the rate at which it is charged.

Cost of the energy harvesting method

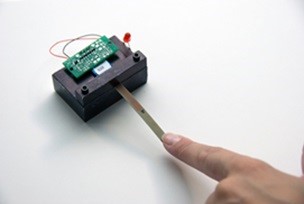

The cost of the energy harvesting method may in some cases be very high, due to the materials used in these devices as well as the conditions under which these devices are deployed. For example, energy harvesting from solar may require overcharge protection, due to the unpredictability of solar energy, while vibrational energy harvesting may require special materials to generate energy. This would add to the cost of deployment.

Suitability of the method for the application

Not all methods of energy harvesting are suitable for all applications. For example, a solar-powered IoT device may not work for an application in an underground mine. Similar things could be said about thermal and vibration-based energy harvesters in applications where the thermal source of power or the vibration energy is respectively weak. So, it is essential to identify the synergy between the energy harvesting method and the application for which it will be employed.

Battery replacement is a cheaper alternative

Industrial IoT follows the integration of a large number of sensors, in most cases. Implementing a potentially disruptive technology such as energy harvesting on a large scale is likely to be more expensive, especially in areas where simple battery replacement would prove to be a cheaper and more efficient application.

Battery replacement / Life

If replacing a battery is infrequent and easy to accomplish, then the economics favor this approach, if externalities such as environmental impacts are ignored. For example, an IoT device that has a design life of 5 years and is intended to be replaced at that point with a battery life of 4-8 years likely does not benefit from an energy harvester approach.

It needs to be noted that while energy harvesters have a significantly lesser environmental footprint, they do not generate the same amount of energy as that a conventional battery. This may change as technologies improve though.

In addition, the need for such a device may be negated with significant advancements in battery technology, that could make them much more efficient and long-lasting. So, the choice of adopting Energy harvesting IoT devices should be made only after careful evaluation of its pros and cons along with the use case or application.

Furthermore, it may not be prudent to adopt Energy Harvesting devices for applications that would be better suited to a wired IoT device, such as a wind turbine, where the wiring would be fairly straightforward and power is available in close proximity.

Even as Energy Harvesting offerings are becoming more available for use in the connected plant, they may not find suitable applications in all settings. For example, it would not be feasible to adopt this technology for organizations that have industrial assets in close proximity to each other, with inspections being performed by maintenance professionals routinely, or in places where the cost of battery replacement is low.

Conclusion

With rapid advancements in material science and technology, newer energy harvesting methods and storage devices with better performance cycles are making their way into the industrial IoT sector, thereby paving the way for energy harvesting wireless sensor networks to become a viable technology choice for a host of applications.

Contact Nanoprecise to know more about AI-based Predictive Maintenance Solutions with Energy Harvesting Wireless IIoT Sensors.