Predictive Maintenance in Pulp and Paper

Equipment failures in pulp and paper mills may be traced back to insufficient maintenance investment before issues are severe. Preventing an issue is considerably more cost-effective than addressing it later, just as it is in any other industry.

Introduction

Pulp and paper makers are finding it increasingly difficult to safeguard their operating margins due to volatile global economic conditions, ever-tougher regulations, and equipment failures.

Rising energy and raw material costs, as well as the constraints of complying with health, safety, and environmental laws, have exacerbated the problem.

As a result, mills are looking for ways to optimize costs, one of which is lowering maintenance tasks while increasing plant availability and uptime. As a result, mills are looking for ways to optimize costs, one of which is lowering maintenance tasks while increasing plant availability and uptime.

New age problems need new-age solutions

Historically, manufacturing processes were shut down on a regular basis for periodic inspections, whether or not they were required.

In today’s world of continuous operations, even planned shutdowns, have become increasingly expensive.

Thankfully, the periods between such shutdowns can be prolonged by using Industrial IoT sensors for condition monitoring.

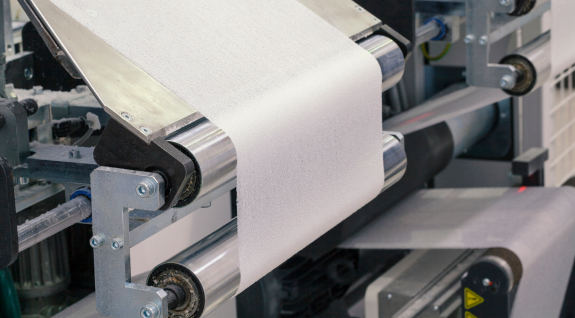

Expensive bearing failures, which impair the paper quality and cause production to stop, are one of the most common concerns in the paper mill’s press section.

In many circumstances, bearing damage causes the entire bearing to cease spinning, causing serious damage to the roll shaft.

Predictive Maintenance Solutions for pulp and paper industry

Paper machines are extremely complex and contain a huge number of expensive parts that wear out during manufacturing.

Using our agile service approach, we analyze the six available data points from the equipment sets, to offer actionable insights that significantly enhance the maintenance of critical assets and facilitates effective failure management.

Our job is to assist clients in better anticipating and optimizing the servicing needs of the machines automated predictive analytics solution.

To create a life cycle model, we deploy reports based on advanced analytics. We help lessen the risk of unplanned shutdowns by using data derived from the Condition Monitoring Sensors.

What makes us unique?

- We have helped countless asset-intensive firms reduce machine downtime, improve performance and dependability while cutting maintenance costs by focusing your expert-level personnel on true value-add activities.

- We are experts not just in data science, but also in providing analysis-based results as part of our fully operational, automated solutions.

- Our solutions integrate analytics into our customers’ business processes, resulting in better results and higher returns at each decision point.

- With Nanoprecise, you can make use of the full possibilities of advanced analytics and AI, without the need for an army of data scientists due to the highly focused use case we are working with.

- All without the need for long learning cycles typically required from data science projects and a minimal amount of information on your machinery.

Why Nanoprecise?

We keep a close eye on the machines that keep your business running smoothly. By predicting issues in advance, our solutions assist our clients to avoid unplanned downtime and reduce headache situations. Participate in the Industry 4.0 Revolution today and start your journey to success. We employ cutting-edge technology to cater to the maintenance needs of our clients. We are a close-knit group of people who are energized by the prospect of assisting businesses in becoming safer, greener, and more efficient. Your operational excellence is just a call away.

Request a Call Back

Frequently Asked Questions

Let us show you how!

Explore the transformative potential of predictive maintenance. At Nanoprecise, we specialize in tailoring predictive maintenance to your unique needs. Reach out today, and together, let’s pave the way for a more efficient, profitable and sustainable future.